Yes, there are substantial cost-effective PC/ABS alternatives available in the Asian market.

These generally fall into two categories: Material Substitutes (switching to Modified PP or High-Heat ABS for less demanding applications) and Strategic Sourcing Substitutes (switching from premium Western brands to specialized Asian compounders). By leveraging the integrated petrochemical supply chains in China, Thailand, and Vietnam, manufacturers can typically reduce material costs by 15% to 30% while maintaining compliance with ISO and automotive standards.

If you are facing pressure to reduce your Bill of Materials (BOM) cost, here is a breakdown of your best options.

Option 1: Material Substitution (The Technical Pivot)

If your part does not require the absolute peak performance of PC/ABS (e.g., extreme impact strength at -40°C), you can switch to a less expensive polymer matrix.

1. Modified Polypropylene (Modified PP)

For many automotive interior parts, PC/ABS is “over-engineered.”

- The Swap: Mineral-filled or Glass-fiber reinforced PP.

- Pros: Significantly lower density (lighter weight = lower cost per part), excellent chemical resistance, and lower raw material price.

- Cons: Lower heat deflection temperature (HDT) and lower gloss compared to PC/ABS.

- Best For: Door panels, lower dashboard trims, and seat components.

Sourcing Tip: Looking for low-odor options? Check our guide on Low VOC Materials to meet global standards.

2. High-Heat ABS

If heat resistance is the concern, but impact requirements are moderate.

- The Swap: Specialized Heat-Resistant ABS grades.

- Pros: Cheaper than PC/ABS, easier to process (better flow), and no need for the expensive Polycarbonate component.

- Cons: Lower impact strength than PC/ABS.

- Best For: Grilles, mirror housings, and electronics housings not exposed to high impact.

Option 2: Strategic Sourcing (The Supply Chain Pivot)

Often, engineers cannot change the polymer type because the mold is already built or the OEM validation is set. In this case, the “alternative” is Changing the Source.

Many global companies still buy PC/ABS from major Western chemical giants. However, the Asian market has matured. Specialized compounders like Kumho Sunny offer “Drop-in Replacements”—materials that match the technical data sheet (TDS) of major brands but at a significantly more competitive price point.

Why Sourcing from Asia (Kumho Sunny) is Cheaper:

- Vertical Integration: Asia dominates the global supply of ABS and Polycarbonate feedstock, reducing logistics and raw material costs.

- Manufacturing Efficiency: Our factories in China and Vietnam/Thailand leverage advanced twin-screw extrusion technology with lower operational overheads.

- No “Brand Premium”: You pay for the molecule and the engineering, not the legacy brand name.

Risk Assessment: “Cheap” vs. “Cost-Effective”

When seeking alternatives, the biggest fear is quality failure. A cheap material is not cost-effective if it causes production downtime.

Common risks when switching to low-cost generic suppliers include:

- Inconsistent Color: Batch-to-batch variation.

- Silver Streaks: Due to high moisture content or poor compounding.

- Poor Impact Strength: Due to using low-quality recycled feedstock.

To mitigate this, you must insist on IATF 16949 certification and request a full material validation report.

Technical Insight: Worried about defects when switching materials? Read our expert guide on Troubleshooting Common PC/ABS Injection Molding Defects to see how we ensure quality.

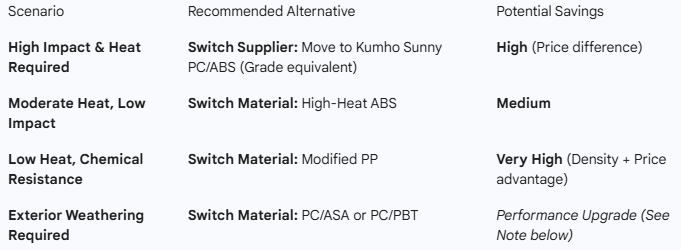

Summary: Which Alternative is Right for You?

Use this quick decision matrix to choose your cost-reduction path:

Get a Cost Analysis Today

Don’t guess. Send us your current material grade and target price. Our application engineers will recommend the exact Kumho Sunny equivalent or a Modified PP solution to hit your cost targets.

Post time: Jan-21-2026