A Tribological Approach to Eliminating the “Stick-Slip” Phenomenon in the EV Era

Author: Senior Material Engineer, Kumho Sunny R&D Center

Category: NVH Solutions / Automotive Interiors / Material Science

Read Time: 10 Minutes

Abstract

As the automotive industry pivots toward electrification, the absence of internal combustion engine (ICE) masking noise has lowered the cabin noise floor by approximately 3-5 dB. This acoustic silence has unmasked a critical quality issue: Squeak and Rattle (S&R). This technical paper analyzes the tribological root causes of friction-induced noise, specifically the “Stick-Slip” phenomenon. We evaluate the efficacy of permanently modified anti-squeak thermoplastics (PC/ABS and ABS alloys) against traditional post-processing methods (felts/tapes). Presenting data based on VDA 230-206 and GMW16853 standards, we demonstrate how intrinsic material modification offers a superior, low-VOC, and cost-effective solution for next-generation interiors.

1. The Physics of Noise: Understanding “Stick-Slip”

To solve Squeak and Rattle, we must distinguish between the two. “Rattle” is impact-induced (components hitting each other due to gaps). “Squeak” is friction-induced. The latter is the complex material science challenge.

The root cause of squeak is the Stick-Slip phenomenon. When two polymer surfaces slide against each other (e.g., a dashboard contacting a vent bezel), the motion is not always continuous. It proceeds in a jerky pattern determined by the difference between the Coefficient of Static Friction and the Coefficient of Kinetic Friction.

When Δμ is positive and large, energy accumulates during the “stick” phase (elastic deformation of surface asperities) and releases suddenly during the “slip” phase. This rapid release generates vibrations in the audible frequency range (200 Hz – 10 kHz).

The Engineering Goal: To minimize Δμ and flatten the friction curve, ensuring a smooth transition from static to kinetic motion. A material pair with a positive friction slope (velocity dependence) will inherently dampen vibrations.

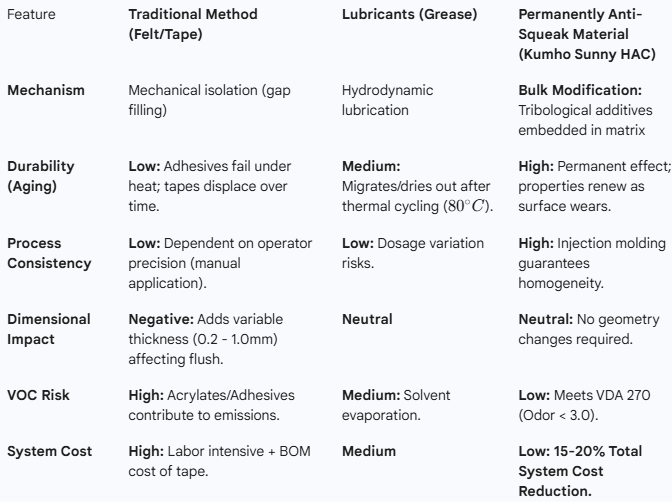

2. Methodology Comparison: Add-on Solutions vs. Modified Plastics

Traditionally, OEMs have relied on “band-aid” solutions: applying felt strips, grease, or flocking tape at contact points. While effective temporarily, these methods introduce process instability, human error, and long-term failure risks.

The modern approach, championed by Kumho Sunny’s HAC (Hyper Anti-Squeak) Series, involves modifying the polymer matrix itself with permanent tribological additives.

Table 1: Comparative Analysis of Squeak Reduction Methodologies

Key Takeaway: While the raw material cost per kg of Anti-Squeak PC/ABS is higher than standard resin, the elimination of manual assembly steps results in significant total system savings.

3. Technical Deep Dive: Validation Standards and Data

At Kumho Sunny, we do not rely on subjective listening tests. We utilize industry-standard quantifiers based on Ziegler Stick-Slip testing methodologies.

3.1 The Testing Standard

We validate our materials against global OEM standards, most notably:

- VDA 230-206: Determination of the stick-slip behavior of material pairs.

- GMW16853: Squeak and Rattle Performance of Interior Trim.

- PSA B62 0030: Sliding friction noise behavior.

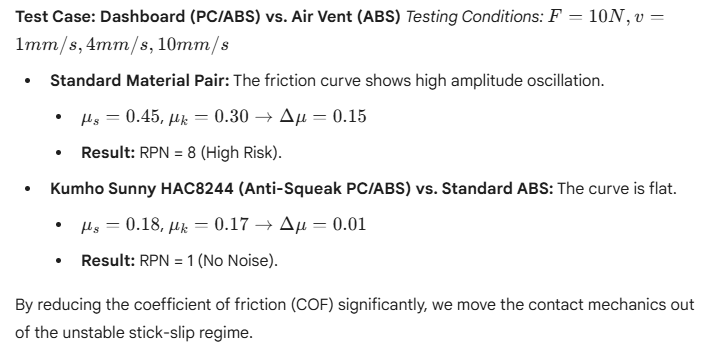

3.2 Friction Coefficient Analysis (Data Interpretation)

The “Risk Priority Number” (RPN) is calculated based on the impulse rate and amplitude of the stick-slip curve.

- RPN 1-3: Green Zone (No audible noise).

- RPN 4-5: Yellow Zone (Risk of noise).

- RPN 6-10: Red Zone (Severe Squeak).

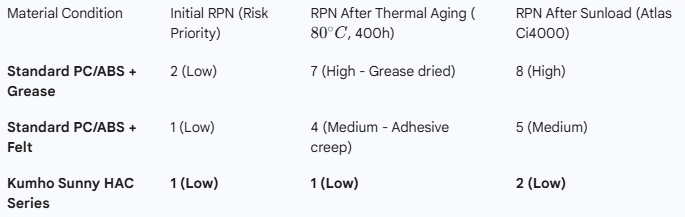

4. Environmental Resistance: The “Aging” Factor

A critical failure mode for automotive interiors is the return of noise after 1-2 years of vehicle usage. This occurs because volatile lubricants evaporate, or felt tape adhesives degrade under thermal cycling.

Our modified plastics undergo rigorous Hydrothermal Aging Tests to ensure the tribological additives do not migrate excessively or degrade.

Chart 1: Friction Stability After Aging Simulation

This data confirms that bulk-modified plastics provide a “Life of Vehicle” solution, unlike temporary surface treatments.

5. Beyond Acoustics: VOC and Lightweighting

Addressing NVH cannot come at the expense of environmental health or vehicle weight.

5.1 VOC and Odor Control

Using “tape-free” assembly removes acrylic adhesives, a primary source of volatile organic compounds (aldehydes/ketones).

5.2 Lightweighting Contribution

The HAC series is formulated with high-flow properties, allowing for thinner wall sections without warping.

6. Engineering Guidelines: Material Pairing Strategy

Squeak is a system property, not just a material property. It depends on the pair of contacting materials.

Best Practices for Material Selection:

- Dissimilar Pairs: The best acoustic performance is achieved when pairing dissimilar polymers (e.g., PC/ABS vs. PP). However, due to design constraints, similar pairs (PC/ABS vs. PC/ABS) are often unavoidable.

- The “One-Side” Rule: For cost efficiency, it is usually sufficient to use the Anti-Squeak material on only one side of the interface (e.g., the bezel) while keeping the main structure (e.g., the instrument panel) as standard material.

- Hardness Differential: Ensure a hardness differential where possible. The Kumho Sunny HAC series is engineered to be slightly softer on the surface (micro-hardness) to facilitate better mating, even if the bulk stiffness (Modulus) remains high.

Typical Application Scenarios:

- Center Console Skeleton: Interface with buttons and cup holders.

- Door Trim Map Pockets: Interface between PP door panel and PC/ABS inserts.

- HUD (Head-Up Display) Housing: Critical area for heat-induced stick-slip.

7. Conclusion: The “Fit and Forget” Solution

In the era of the Software-Defined Vehicle, hardware quality is judged by silence. Squeak and rattle are no longer acceptable annoyances; they are perceived as functional failures.

By shifting the solution from the assembly line (manual tapes) to the material science lab (modified PC/ABS), OEMs can achieve:

- Permanent Noise Reduction (Durability).

- Process Simplification (No secondary ops).

- Healthier Cabins (Reduced VOCs).

Kumho Sunny remains committed to pushing the boundaries of polymer modification. Our HAC Series is not just a material; it is a validated engineering solution for the quiet cabin of the future.

Post time: Jan-21-2026