In the New Energy Vehicle (NEV) and energy storage industries, “spontaneous combustion” and “thermal runaway” are the swords of Damocles hanging over every brand. As protective devices for battery systems, flame-retardant plastics must not only possess basic fireproofing properties but also combat the “invisible killer” in long-term high-temperature and high-humidity environments: hydrolysis. Deeply rooted in the modified plastics sector, Kumho-Sunny has addressed the significant performance degradation of traditional materials under hot and humid conditions by launching systematic solutions that combine high toughness with superior hydrolysis resistance.

Core Product Advantages :

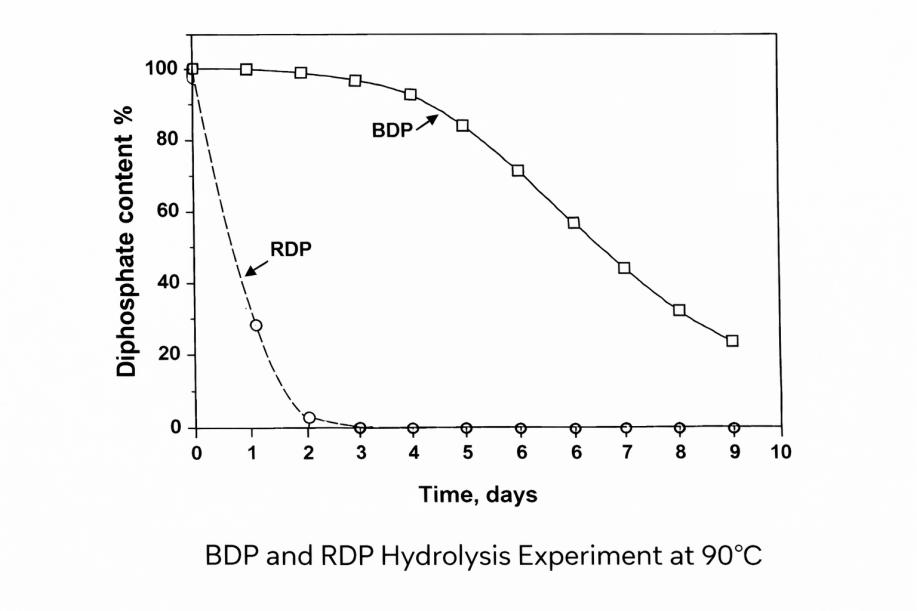

Tackling the “Hydrolysis” Pain Point to Ensure Long-lasting Shell Integrity: Conventional flame-retardant PC/ABS often suffers from molecular chain scission caused by catalyst-induced degradation from flame retardants in “Double 85″ (85°C / 85% humidity) environments, making the material as “brittle as paper”. Through independent research and development, Kumho-Sunny has significantly improved the heat and moisture resistance of these materials. Rigorous aging tests show our flame-retardant PC/ABS far exceeds industry standards in toughness retention, ensuring that Battery Management Systems (BMS) and protective casings do not crack or fail due to environmental factors throughout their entire life cycle.

A Comprehensive Balance of Physical Properties:Compared to expensive MPPO or reinforced nylon (PA) that is prone to moisture absorption and deformation, Kumho-Sunny’s products find the “Golden Ratio” between cost and performance. Our materials not only feature excellent flame-retardant ratings but also exhibit outstanding impact strength and dimensional stability. They effectively absorb collision energy to prevent electrolyte leakage caused by external forces, reducing the risk of short-circuit-induced combustion at the source.

Weather Resistance for Extreme Outdoor Conditions:In outdoor scenarios like charging piles and photovoltaics, materials often “become brittle from sun exposure before they even hydrolyze”. Kumho-Sunny’s weather-resistant flame-retardant series maintains superior hydrolysis resistance while significantly enhancing UV aging resistance. This ensures products retain their appearance and structural strength even after long-term exposure to wind and sun, moving away from the “dilapidated” feel of low-end materials.

Systematic Service for Precise Material Selection:We adhere to a “tailor-made” R&D philosophy. Kumho-Sunny provides more than just plastic granules; we offer a closed-loop solution covering mold optimization, injection molding process guidance, and failure analysis. This helps enterprises achieve comprehensive cost reductions while pursuing ultimate performance.

Kumho-Sunny understands that the stability of every material is linked to the protection of a life. Choosing us means equipping your battery system with “body armor,” allowing you to win through reliable quality in the new energy race.

Post time: Dec-29-2025