In today’s rapidly developing new energy infrastructure sector, the cracking of charging piles has become a hidden danger affecting both product safety and brand reputation. Charging piles are exposed to complex and volatile outdoor environments for long periods, facing multiple challenges such as low-temperature embrittlement, internal stress accumulation, and corrosion from cleaning solvents. Leveraging deep R&D experience in modified plastics, Kumho-Sunny has conducted in-depth analyses of “crack-inducing” factors to provide the industry with “targeted” high-reliability material solutions.

Our Core Product Advantages:

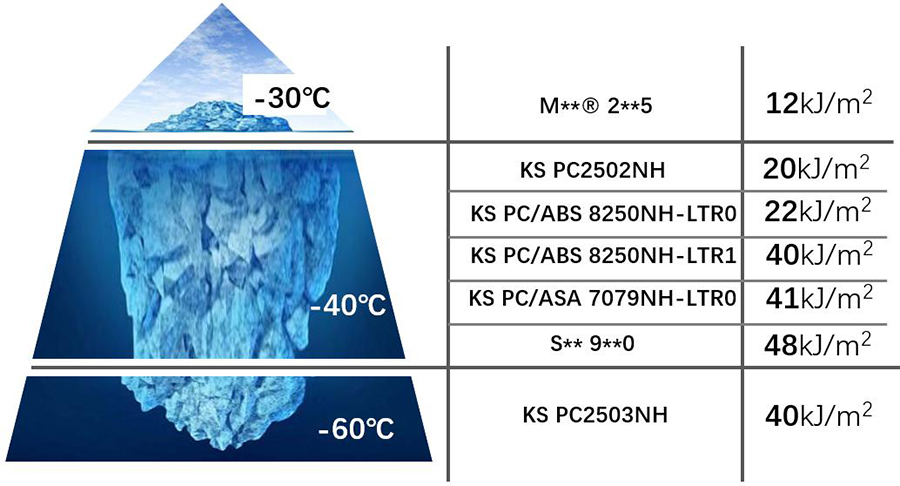

Excellent Low-Temperature Toughness, Defying Extreme Cold:

In response to the extreme low temperatures in high-latitude regions, our anti-freezing series products demonstrate exceptional impact resistance. Compared to ordinary materials on the market that become “as brittle as glass” in the cold, Kumho-Sunny’s super-tough PC/ABS (such as HAC8244) optimizes molecular structures to maintain extremely high impact strength even at -40°C or lower, ensuring that charging pile housings remain tough and intact during harsh winters

Micro-Nano Phase Technology for Superior Chemical Resistance:

To address environmental stress cracking (ESC) caused by contact with cleaning agents, rust-preventative oils, and other chemicals during daily maintenance, we have introduced PC/PBT K8550NH. Utilizing an advanced micro-nano phase structure, this product not only delivers mechanical strength far exceeding international competitors (with notched impact strength increased by over 3 times) but also performs robustly in various corrosive solvent tests.

Outstanding Anti-Deformation and Dimensional Stability:

Large charging pile housings are prone to warping during injection molding, and subsequent assembly stress is a major trigger for cracking. Kumho-Sunny’s products feature lower shrinkage rates and stronger anti-deformation properties, significantly reducing internal stress in the parts. In comparative tests on 150mm*150mm plaques, our materials significantly outperformed competitors, providing a guarantee for precision assembly and long-term reliability.

The Perfect Balance of Cost and Performance:

We fully understand the industry’s pursuit of cost-effectiveness. While maintaining leading mechanical performance (with elongation at break more than 4 times that of competitors), Kumho-Sunny has endowed its products with stronger price competitiveness through process optimization, helping customers achieve optimal costs while improving product quality.

|

|

Kumho-Sunny does not just provide materials; we offer systematic solutions encompassing material selection guidance, mold optimization, and failure analysis. We firmly believe that through “targeted” precision in material selection—matching the right material to the specific challenge—the chronic problem of charging pile cracking can be thoroughly resolved. Choosing Kumho-Sunny means choosing to safeguard your product’s safety and ensuring a steady lead in the new energy race.

Post time: Dec-29-2025