By Jiarong Lu Materials Engineer, Kumho Sunny

Executive Summary

The global manufacturing landscape is undergoing a seismic shift. Triggered by aggressive carbon neutrality targets (such as the EU Green Deal and China’s “Dual Carbon” goals) and increasing consumer demand for sustainability, ESG (Environmental, Social, and Governance) has evolved from a corporate buzzword into a critical engineering constraint. For OEMs in the automotive, electronics, and consumer goods sectors, the challenge is no longer if they should use recycled materials, but how to use them without compromising performance or aesthetics.

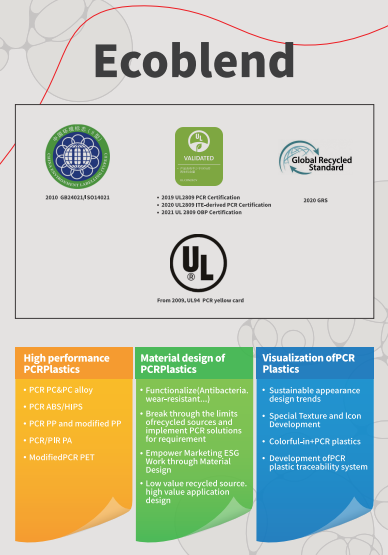

This article explores the technical evolution of Post-Consumer Recycled (PCR) plastics. We move beyond simple mechanical recycling to discuss “Material Design”—a holistic engineering approach that allows PCR to replace virgin engineering plastics in structural and aesthetic applications. Drawing on typical global case studies and Kumho Sunny’s Ecoblend® solutions, we demonstrate how advanced compounding, strict feedstock control, and innovative aesthetic technologies are rewriting the rules of the circular economy.

Part 1: The Strategic Role of PCR in Overseas ESG Strategies

1.1 Tackling Scope 3 Emissions

For most international brands—whether it is Dell, Ford, or Bosch—the vast majority of carbon emissions (often >70%) lie in “Scope 3″: the value chain. Raw material extraction and processing are the largest contributors to this footprint.

Integrating PCR plastics is the most direct lever for reducing Scope 3 emissions. Unlike bio-based materials which can have complex land-use implications, or carbon capture which is capital intensive, PCR offers immediate, quantifiable carbon reduction.

- Data Insight: According to ISO 14067 verifications, replacing virgin material with high-quality PCR can yield massive reductions. For instance, Kumho Sunny’s Ecoblend® ER6100 (100% PCR PP) has a carbon footprint of just 0.77 kg CO2e/kg, compared to the industry baseline for virgin PP. This represents a reduction of 66.04%. Similarly, using PCR PC/ABS (ER9080NH) achieves an 80.73% reduction in carbon emissions.

1.2 Regulatory Compliance and the “Right to Repair”

Global regulations are tightening. The EU’s End-of-Life Vehicles (ELV) Directive and the impending Ecodesign for Sustainable Products Regulation (ESPR) are setting mandatory recycled content thresholds.

- The Challenge: Regulations demand recycled content not just in hidden, non-critical parts (like wheel arch liners), but in visible and structural components.

- The Solution: This necessitates a shift from “downcycling” (turning car bumpers into flower pots) to “upcycling” (turning waste bottles into automotive structural brackets).

Part 2: Typical Case Studies – From “Recycled” to “Preferred”

To understand the viability of PCR in high-stakes industries, we must look at how leading global players are deploying these materials. The following case studies illustrate the transition of PCR from a “cost-saving” option to a “value-adding” solution.

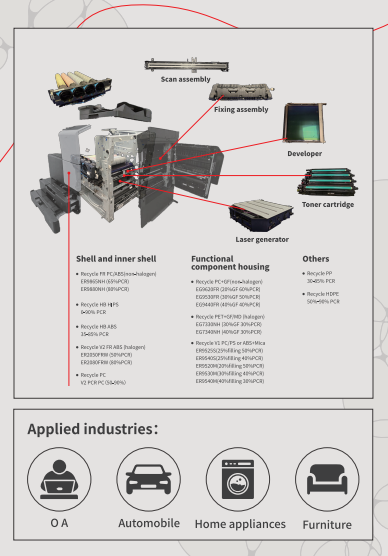

2.1 Office Automation (OA): The “Closed Loop” Pioneers

The OA industry (printers, copiers) was among the first to adopt PCR due to strict EPEAT and Blue Angel certification requirements.

- The Industry Standard: Brands like Canon, Ricoh, and Brother require materials that offer dimensional stability comparable to virgin ABS or HIPS, alongside strict chemical safety (RoHS/REACH compliance).

- The Kumho Sunny Solution:

- Konica Minolta utilizes a suite of Ecoblend® materials, including ER6050 (50% PCR PP) for internal chassis components and PC/PET-NH (72.05% PCR) for exterior housing.

- Technical Win: The PC/PET-NH grade is particularly notable. It is a halogen-free flame retardant alloy containing over 70% recycled content. Achieving a UL94 V-0 rating with such high PCR loading requires sophisticated compatibilization technology to prevent the degradation of the PET matrix during re-extrusion.

2.2 Automotive: Breaking the “Safety Critical” Barrier

Automotive OEMs have historically been hesitant to use PCR in structural parts due to concerns over batch-to-batch consistency and impact strength. However, the pressure to reduce vehicle lifecycle carbon footprints is driving innovation.

- Case Study: Ford Motor Company

- Application: Rearview Mirror Bracket (Model: Forrest C490).

- Material: Ecoblend® EG3550G, a PBT/rPET alloy with 50% glass fiber reinforcement and 18% recycled PET content.

- Engineering Challenge: This part requires high rigidity to prevent mirror vibration and high weather resistance (UV stability).

- The Result: By modifying the crystallization kinetics of the rPET and using reactive extrusion to rebuild molecular weight, the Ecoblend material matched the performance of the original virgin PBT+GF50. It offered a stable recycled source and lower cost while meeting all OEM specifications for strength and durability.

2.3 Consumer Electronics: The Intersection of Aesthetics and Ecology

In consumer electronics, the material must look as good as it performs. Consumers want sustainable products, but they often reject products that look like recycled waste (e.g., featuring black spots or flow lines).

- Case Study: Lenovo All-in-One (AIO 520)

- Application: Computer Shell.

- Material: White PCR ABS utilizing Colorful-in® technology.

- Innovation: Traditionally, PCR ABS is limited to black or dark grey colors due to impurities in the feedstock. Kumho Sunny utilized “Colorful-in” (paint-free aesthetic plastic) technology to create a custom white color with a high-gloss finish. This eliminated the need for spray painting—a process that is VOC-intensive and detrimental to recycling—thereby creating a “double green” benefit: Recycled Material + Elimination of Painting.

2.4 New Mobility: Shared Economies & Micromobility

The shared economy demands extreme durability. Bikes and scooters are left outdoors, abused, and exposed to the elements.

- Case Study: Meituan & Segway-Ninebot

- Applications: Bicycle baskets, seat bases, and scooter fenders.

- Materials: PCR PP (ER6100 series) and PCR PC/ABS (65% PCR).

- Performance: The bicycle basket uses PCR PP reinforced with 5% Talc (TD5), incorporating 10% single-use packaging PP. This formulation was specifically designed to resist cold-weather cracking (low-temperature impact strength) and UV degradation, proving that packaging waste can be upcycled into durable goods.

Part 3: Technical Highlights – The Engineering Behind Ecoblend®

The success of the case studies above is not accidental. It relies on a rigorous engineering framework Kumho Sunny calls “Material Design.” This approach addresses the three critical failures of generic recycled plastics: Instability, Degradation, and Aesthetic Limitations.

3.1 The “Triangle of Control”: Ensuring Consistency

The primary objection to PCR is inconsistency. Kumho Sunny mitigates this through a tripartite control system:

- Raw Materials (The Feedstock): We do not simply buy “recycled pellets.” We manage the source. Whether it is post-consumer water buckets, woven bags, or ocean-bound fishing nets, we implement a strict Supplier Audit and Pilot Production phase before approval. Every batch undergoes constituent analysis (DSC/TGA) and hazardous substance screening (RoHS).

- Processing Technology (The Hardware): Recycling degrades polymer chains. To counter this, we optimize the screw combination to provide shear without overheating (which causes further degradation) and employ high-efficiency vacuum control to remove volatiles and oligomers common in waste streams.

- Recipe (The Chemistry): This is the core IP. We utilize reactive extrusion additives—compatibilizers, chain extenders, and toughening agents—to rebuild the polymer matrix.

3.2 Upcycling Ocean Bound Plastics (OBP): A Chemical Challenge

Ocean Bound Plastics (OBP) are notoriously difficult to recycle due to salt contamination and hydrolytic degradation from UV and seawater exposure. However, they represent a massive ESG opportunity.

Kumho Sunny has successfully industrialized OBP solutions, specifically OBP PC/PET.

- The Grade: KCA9341NH (42.5% PCR, including 12.5% OBP).

- Performance Data:The Engineering: By developing a customized compatibilizer for the PC and OBP-PET interface, we overcame the brittleness typically associated with salt-degraded PET. This allows brands to claim “Ocean Plastic” content without risking mechanical failure in structural parts.

- Tensile Strength: 62 MPa (Matching virgin PC/ABS).

- Impact Strength (Notched Izod): 600 J/m (Excellent toughness).

- Flammability: UL94 V-0 at 1.6mm.

3.3 OBP Modified ABS: Beating Virgin Standards

Standard PCR ABS often suffers from a drop in impact strength. Through our proprietary “Material Design,” Ecoblend® OBP-modified ABS actually outperforms general-purpose virgin ABS.

- Comparison:Significance: This nearly doubles the toughness of virgin material, allowing engineers to thin-wall parts to save weight (further reducing carbon) while using recycled content.

- General Virgin ABS Impact Strength: 180 J/m.

- Ecoblend® ABS-MP (15% OBP): 336.06 J/m.

3.4 Aesthetic Revolution: Colorful-in® + PCR

Sustainability usually comes in one color: Black. This limits design freedom. Kumho Sunny combines Ecoblend® with Colorful-in® technology to offer:

- Defect Hiding: Specialized textures (like “Geometric Twill” or “Honeycomb”) and speckled effects (like “Denim Blue” or “Bare Sand Pottery”) visually mask the tiny black spots or gels inherent in PCR.

- Market Appeal: This transforms the “flaw” of recycled material into a “feature”—a unique, natural aesthetic that communicates sustainability to the consumer without words.

Part 4: Verified Sustainability (Data & Certifications)

In the overseas market, “greenwashing” is a legal risk. Data transparency is paramount. Ecoblend® provides a robust compliance package:

4.1 Certification Portfolio

- UL 2809 Validation: Validates the exact percentage of PCR content (e.g., Post-Consumer, ITE-derived, OBP).

- GRS (Global Recycled Standard): Ensures chain-of-custody tracking from the waste bin to the final pellet.

- Carbon Footprint (ISO 14067): Third-party verified data by TÜV Rheinland.

4.2 The Carbon Advantage

Engineers can calculate their ESG contributions directly using our certified data.

- Virgin ABS: ~3.6 kg CO2e/kg (Industry Avg).

- Ecoblend® ABS-M1 (85% PCR): 1.53 kg CO2e/kg (50% Reduction).

- Virgin PC/ABS: ~4.0 kg CO2e/kg (Industry Avg).

- Ecoblend® PC/ABS K8269 (65% PCR): 2.05 kg CO2e/kg (71.89% Reduction).

Conclusion: Partnering for the Future

The era of choosing between “Sustainability” and “Performance” is over. Through advanced compounding technologies, rigorous quality control, and innovative material design, Kumho Sunny’s Ecoblend® portfolio proves that PCR plastics can meet the demanding specifications of the automotive, electronics, and consumer industries.

For overseas enterprises navigating the complexities of ESG reporting and Scope 3 reduction, Ecoblend® offers a turnkey solution: materials that are mechanically robust, aesthetically versatile, and rigorously certified.

Ready to redesign your material strategy? Contact our engineering team to explore how Ecoblend® can be tailored to your specific application needs.

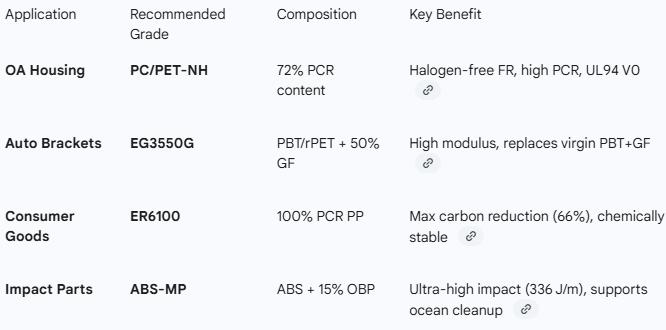

Appendix: Key Material Recommendations

|

|

|

Post time: Dec-22-2025