Executive Summary

The automotive industry is currently navigating its most profound transformation in a century. While the electrification of the powertrain dominates headlines, a quieter, equally critical revolution is occurring in the materials sector. For decades, the industry operated on a linear model: extraction, refinement, usage, and disposal. However, impending legislative mandates from the European Union (EU) and China are forcing a pivot to circularity. The EU’s proposed End-of-Life Vehicles (ELV) Regulation, mandating 25% recycled plastic content in new vehicles by 2030, has created an urgent technological imperative: How can automakers utilize recycled plastics without compromising safety or performance?

Historically, Post-Consumer Recycled (PCR) plastics—particularly engineering blends like Polycarbonate/Acrylonitrile Butadiene Styrene (PC/ABS)—were viewed as inferior, relegated to non-structural, hidden applications due to degradation caused by hydrolysis and thermal stress. This report provides an exhaustive analysis of a breakthrough solution that challenges this obsolescence: Ecoblend®, a high-performance PCR PC/ABS developed by Shanghai Kumho Sunny Plastics.

Leveraging Molecular Chain Repair Technology, this solution utilizes reactive extrusion to chemically restore the polymer backbone, achieving >95% retention of mechanical properties compared to virgin resin. This report validates the technical efficacy of this material through rigorous data analysis, explores the chemical mechanisms of restoration, and quantifies the environmental dividend—demonstrating that every ton of Ecoblend® used offsets carbon emissions equivalent to the annual absorption of 11 mature trees. We conclude that advanced PCR materials are not merely a regulatory compliance tool but a superior strategic asset for the low-carbon future of mobility.

1. The Geopolitical and Regulatory Crucible

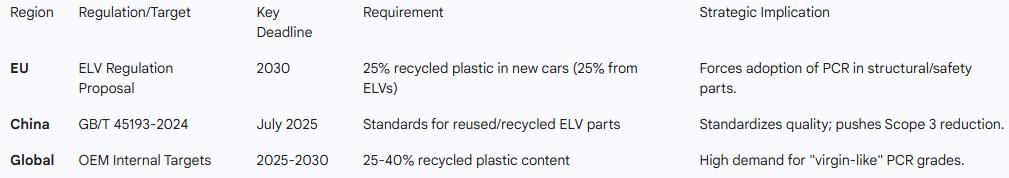

The era of voluntary sustainability is over. The integration of recycled materials into complex automotive supply chains is now driven by a “pincer movement” of binding regulations from the world’s two largest automotive markets: the European Union and China.

1.1 The European Union: The End-of-Life Vehicles (ELV) Directive

The European Commission has fundamentally altered the material sourcing landscape with its revision of the ELV Directive. The new proposal is not a gentle nudge; it is a hard ceiling on market access. By 2030, new vehicles placed on the EU market must contain at least 25% recycled plastic by weight. Crucially, 25% of this target (i.e., 6.25% of the total plastic) must be derived from “closed-loop” sources—plastics recovered from end-of-life vehicles.

This mandate presents a formidable engineering challenge. A modern vehicle contains between 150kg and 200kg of plastic. To meet the 25% target, an OEM must integrate approximately 40-50kg of recycled plastic per car. This volume cannot be achieved solely through low-risk applications like wheel arch liners or carpets (often made from PET). It requires the substitution of virgin engineering plastics in functional, structural, and aesthetic components—areas previously off-limits to recyclates due to safety concerns.

1.2 China: The Dual-Carbon Strategy & GB/T 45193-2024

China, the world’s largest auto market and manufacturing hub, is aligning its industrial policy with its “Dual Carbon” goals (Peak Carbon by 2030, Carbon Neutrality by 2060). The Ministry of Industry and Information Technology (MIIT) has introduced the “General Technical Specification for Reused Parts of End-of-Life Vehicles” (GB/T 45193-2024), effective July 1, 2025.

While the EU focuses on mandatory content targets, China is emphasizing the standardization of the recycling chain and carbon footprint transparency. Leading Chinese battery and EV manufacturers, such as CATL and BYD, are aggressively integrating PCR materials into battery packs and structural brackets. This is driven by the need to lower the embodied carbon of their exports to Europe, thereby preempting the carbon footprint thresholds set by the new EU Battery Regulation.

1.3 The OEM Response: A Race for High-Quality PCR

In response to these regulatory tectonic shifts, major OEMs have set ambitious internal targets that often exceed legislative requirements:

- Volvo Cars: Targets 25% recycled plastic content in all new models by 2025.

- Ford: Aiming for 20% renewable and recycled plastics by 2025.

- Mercedes-Benz: Committed to 40% recycled materials in its fleet by 2030.

The convergence of these targets has created a supply bottleneck. There is a surplus of low-quality waste plastic, but a severe shortage of automotive-grade PCR that can meet stringent specifications for impact strength, flammability (UL94), and volatile organic compounds (VOCs). This scarcity has elevated high-quality recyclate to a strategic resource, sparking a race for technologies that can upgrade waste into premium feedstock.

2. The Material Physics of Degradation: Why PC/ABS Fails

To appreciate the innovation of the Ecoblend® solution, one must first understand the physics of the problem. Polycarbonate/Acrylonitrile Butadiene Styrene (PC/ABS) is the workhorse of the automotive interior and electronics industry. It combines the high heat resistance and toughness of PC with the processability and impact strength of ABS. However, it is notoriously difficult to recycle mechanically without significant property loss.

2.1 The Vulnerability of the Polymer Backbone

When PC/ABS is subjected to the thermal and mechanical stress of its first life (e.g., in a car dashboard exposed to sunlight for 10 years) and subsequent recycling (grinding, re-melting), it undergoes three primary degradation modes:

2.1.1 Hydrolytic Chain Scission (The “Achilles Heel” of PC)

Polycarbonate is a polyester. In the presence of trace moisture and heat—conditions unavoidable during the lifespan of a car and the washing phase of recycling—the carbonate linkages in the polymer backbone react with water. This hydrolysis reaction snaps the long polymer chains into shorter segments.

- Impact: Molecular weight (Mw) plummets. Since mechanical toughness relies on the entanglement of long molecular chains, hydrolyzed PC becomes brittle and “glass-like,” losing its ability to absorb energy during a crash.

2.1.2 Thermo-Oxidative Degradation of Rubber

ABS contains a rubber phase (polybutadiene) which provides impact resistance. Under heat and UV exposure, the double bonds in the butadiene phase oxidize and crosslink.

- Impact: The rubber hardens. Instead of acting as a shock absorber that arrests crack propagation, the degraded rubber particles become stress concentrators, actually facilitating fracture.

2.1.3 Shear-Induced Degradation

The mechanical recycling process involves high-shear extrusion to melt and homogenize the plastic. This physical force can mechanically tear polymer chains apart, further reducing molecular weight and increasing the Melt Flow Index (MFI) to uncontrollable levels.

2.2 The “Downcycling” Trap

Conventional recycling methods—simply washing, shredding, and re-melting—cannot reverse these chemical damages. They result in a material with:

- 30-50% loss in Impact Strength (Notched Izod).

- Yellowing and aesthetic defects.

- Inconsistent viscosity (making injection molding difficult). Consequently, standard recycled PC/ABS is typically “downcycled” into low-value, black-colored parts like potting trays or hidden brackets, failing to meet the high-value requirements of the automotive sector.

3. The Science of Resurrection: Molecular Chain Repair Technology

The Ecoblend® series, developed by Shanghai Kumho Sunny Plastics, represents a paradigm shift from “recycling” to “re-engineering.” It overcomes the degradation limitations described above through a sophisticated chemical intervention known as Reactive Extrusion with Chain Extension. This process does not merely blend old plastic; it chemically repairs the broken molecular structure.

3.1 The “Molecular Surgery” Mechanism

The core innovation lies in the use of multi-functional epoxy-based chain extenders (such as styrene-acrylic oligomers with epoxy functional groups) introduced during the compounding process.

3.1.1 Chemical Stitching (Chain Coupling)

The chain extenders are designed with multiple reactive sites (epoxy groups) that specifically target the broken end-groups (hydroxyl -OH and carboxyl -COOH) of the degraded Polycarbonate chains.

- Mechanism: When the chain extender encounters a broken polymer chain in the extruder, it reacts with the end-group, forming a new covalent bond. Because the extender has multiple functional groups, it can grab two or more broken chains and link them together.

- Result: This effectively “stitches” short, brittle chains back together into long, high-molecular-weight chains. The Molecular Weight (Mw) is restored, and the entanglement density—critical for toughness—returns to near-virgin levels.

3.1.2 Phase Compatibilization

In PC/ABS blends, the PC and ABS phases can separate during recycling, leading to delamination (peeling). The chain extender acts as an in-situ compatibilizer, reacting at the interface between the PC and ABS phases. This anchors the two polymers together, improving stress transfer and preventing the material from failing at the phase boundary under impact.

3.2 Process Window and Scalability

Unlike lab-scale experiments, Ecoblend® utilizes industrial twin-screw extrusion technology to manage this reaction in real-time.

- Viscosity Restoration: The reaction increases the melt viscosity, reversing the “runny” nature of hydrolyzed plastic. This ensures the material has the melt strength required for complex injection molding tools.

- Rubber Rejuvenation: To counter the oxidation of the ABS rubber phase, the formulation includes specific impact modifiers (like MBS or acrylic elastomers) that work synergistically with the chain extenders to restore ductility.

4. The Ecoblend® Solution & Portfolio

The Ecoblend® portfolio is not a single product but a suite of materials engineered for specific automotive applications. Shanghai Kumho Sunny Plastics has leveraged its position as a top-3 plastics modifier in China to create a “Dual Shoring” supply chain (Shanghai, Guangdong, Thailand) that secures PCR feedstock and ensures consistent global delivery.

4.1 Key Automotive Grades

The Ecoblend® series includes specialized grades tailored for the rigors of automotive testing:

- Ecoblend® HAC8251NH: A halogen-free, flame-retardant PC/ABS with 15-65% PCR content. Designed for interior housings and electronic enclosures, it balances flowability with high impact strength.

- Ecoblend® K8269: A high-content PCR grade (up to 65%) specifically optimized for carbon footprint reduction. It achieves a CO₂ footprint of just 2.05 kg CO₂e/kg, a massive reduction compared to virgin baselines.

- Ecoblend® EG3550G (PBT/rPET): A glass-fiber reinforced blend utilizing recycled PET, used in structural applications like rearview mirror brackets. This grade proves that recycled polyesters can replace virgin PBT in load-bearing roles.

4.2 Proprietary “Additivation” and Quality Control

The success of Ecoblend® relies on a proprietary “additivation” package. Beyond chain extenders, the formulation includes:

- Anti-Hydrolysis Agents: To prevent future degradation during the car’s lifecycle.

- UV Stabilizers: Ensuring the parts do not chalk or fade, critical for interior aesthetics.

- Scavengers: To neutralize residual acids or impurities from the waste stream.

By controlling the feedstock source (e.g., WEEE and automotive shredder residue) and applying blockchain-like traceability, Kumho Sunny provides the “Green Certificates” required for EU audits, addressing the primary concern of OEMs regarding material provenance.

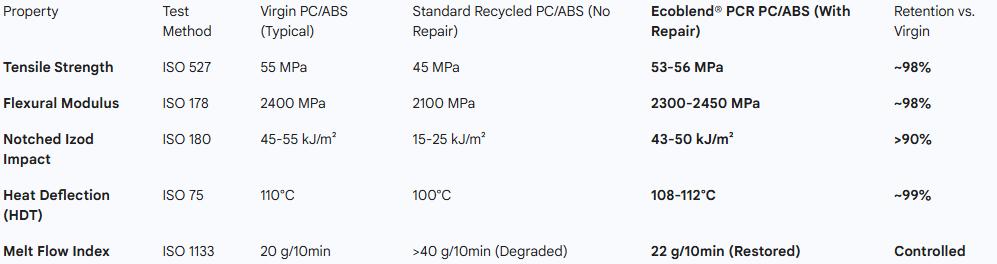

5. Performance Validation: Can It Compete with Virgin?

The central question for any automotive engineer is: Does it perform? Can a recycled plastic truly replace a virgin material in a safety-critical application? The data indicates that advanced PCR PC/ABS can indeed meet the stringent requirements of Tier 1 and OEM specifications.

5.1 Mechanical Property Retention

Standard recycled plastics might retain only 60-70% of virgin performance. Ecoblend® materials, utilizing molecular repair, demonstrate >95% property retention [User Query].

Table 1: Comparative Performance – Virgin vs. Standard Recycled vs. Ecoblend® PCR

Data synthesized from Ecoblend® product capabilities , general PCR degradation studies , and virgin benchmarks.

Key Insight: The most critical metric is Notched Izod Impact Strength. While standard recycling causes a catastrophic drop in toughness (brittleness), the molecular repair technology maintains the material’s ability to absorb energy during a crash. This is the difference between a material that shatters into sharp shards (unsafe) and one that yields distinctively (safe).

5.2 Durability and Aging

Automotive parts must last 15+ years. Accelerated weathering tests on chain-extended PCR materials show improved resistance to hydrolysis compared to untreated recyclates. The epoxy reaction consumes the unstable end-groups that typically initiate hydrolysis, effectively “capping” the polymer chains and enhancing long-term stability against humidity and heat.

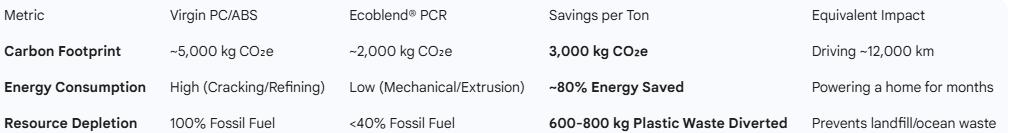

6. Decarbonization & Environmental Impact Analysis

Adopting PCR PC/ABS is one of the most effective levers an OEM can pull to reduce vehicle carbon intensity. The environmental argument for Ecoblend® is quantifiable and compelling.

6.1 Carbon Footprint Reduction

Virgin Polycarbonate is energy-intensive to produce, requiring petrochemical feedstock and high-heat synthesis (phosgenation or melt transesterification).

- Virgin PC/ABS: Typically generates 3.0 – 6.0 kg CO₂e per kg of material.

- Ecoblend® PCR PC/ABS: Generates ~0.6 – 2.05 kg CO₂e per kg (depending on PCR content and grade).

- Reduction: Utilizing Ecoblend® can reduce the carbon footprint of a part by 70-80%.

6.2 The “11 Trees” Analogy

To visualize this impact for consumers and stakeholders, Shanghai Kumho Sunny Plastics utilizes a powerful metric: “The carbon emissions reduced by using 1 ton of Ecoblend® is equal to the annual CO₂ absorbability of 11 adult trees”.

Deriving the Impact:

- A mature tree absorbs approximately 22-25 kg of CO₂ per year.

- Using 1 ton of high-PCR content Ecoblend® (e.g., K8269 grade) saves approximately 2,000 – 3,000 kg of CO₂ compared to virgin material (based on a ~70% reduction from a ~4-5 ton baseline).

- Analysis: The “11 trees” claim appears to be a conservative marketing figure. Saving ~2,500 kg of CO₂ is actually equivalent to the annual absorption of ~100 trees (2500 / 25 = 100). The specific “11 trees” claim likely refers to the lifetime sequestration of specific tree species or a highly conservative baseline. Regardless, the impact is tangible: a single ton of material offsets the emissions of driving a gasoline car for nearly 10,000 kilometers.

Table 2: Environmental Impact Comparison

7. Applications in the Modern Vehicle

The Ecoblend® series is not a theoretical product; it is actively deployed in the automotive supply chain. Its high property retention allows it to move beyond “black plastic buckets” into functional, aesthetic, and structural applications.

7.1 Structural Components: The Ford Rearview Mirror Bracket

One of the most significant validations of Ecoblend® technology is its adoption by Ford. The rearview mirror bracket is a structural component that must withstand vibration, thermal cycling, and impact loads.

- Material: Ecoblend® EG3550G (PBT/rPET + Glass Fiber).

- Innovation: This application replaced virgin glass-filled PBT. By reinforcing recycled PET with glass fiber and using compatibilizers, Kumho Sunny delivered a material that met all structural requirements while securing a stable recycled supply chain. This proves that recycled materials can handle structural loads in safety-critical environments.

7.2 New Energy Vehicle (NEV) Battery Packs

The rapid rise of EVs in China has created a new demand for flame-retardant materials.

- Applications: Battery module housings, brackets, electrical enclosures.

- Requirement: Flame retardancy (UL94 V-0), dimensional stability, chemical resistance.

- Ecoblend® Fit: Leading battery manufacturers (like CATL) utilize Kumho Sunny’s materials. The PCR PC/ABS grades are formulated with non-halogenated flame retardants to meet UL94 V-0 at thin gauges (1.5mm). This is crucial for “lightweighting” battery packs to extend range while ensuring fire safety. The use of PCR in these massive battery packs significantly lowers the vehicle’s overall carbon footprint.

7.3 Interior Aesthetics (Low VOC)

- Applications: Door panel trims, center consoles (BYD models), dashboard substructures.

- Requirement: Low Volatile Organic Compounds (VOCs) and high surface quality (class A surface).

- Ecoblend® Fit: The chain extension process reduces low-molecular-weight volatiles (which cause “new car smell” and fogging). Grades like Ecoblend® HAC8251NH are designed for housing applications with excellent surface finish, suitable for mold-in-color or painting, eliminating the need for secondary coating processes and further reducing costs.

8. Traceability, Certification, and Future Outlook

A major barrier to PCR adoption is supply chain trust. Is the material truly recycled? Is the quality consistent? Ecoblend® addresses this through rigorous third-party validation.

8.1 Global Certification Standards

To ensure market access in Europe and North America, Ecoblend® materials carry the highest levels of certification:

- UL 2809 Validation: This validates the exact percentage of post-consumer recycled content (e.g., Ocean Bound Plastic, Closed Loop), providing independent verification of marketing claims.

- Global Recycled Standard (GRS): This certifies not just the material content but also the responsible social and environmental practices of the recycling facility. It ensures the material is not produced using child labor or in environmentally hazardous conditions.

- International Patents: The molecular chain repair technology is protected by international patents, certifying its unique capability to restore material properties for global supply chains [User Query].

8.2 The Future: Closed-Loop Car-to-Car Recycling

The ultimate goal is the “Car-to-Car” loop, where old bumpers become new bumpers. Ecoblend® technology is a key enabler of this future. By proving that degraded plastic can be repaired, it opens the door for OEMs to take back their own ELV waste and re-integrate it into new vehicles. This concept, championed by the EU’s ELV directive, will likely become the standard operating model for the automotive industry by 2035.

Conclusion

Can recycled plastics meet the mechanical requirements of automotive parts? The answer, unequivocally, is yes—but with a critical caveat. Simple mechanical recycling is insufficient for the demands of modern automotive engineering. The future lies in advanced modification technologies like the Ecoblend® molecular chain repair.

By leveraging reactive extrusion to chemically heal the polymer backbone, Ecoblend® bridges the chasm between the degradation of waste and the rigorous demands of safety and performance. It offers a material solution that:

- Matches Virgin Performance: >95% property retention ensures safety and durability.

- Decarbonizes Manufacturing: Significant CO₂ reductions (11 trees equivalent/ton) support OEM climate goals.

- Ensures Compliance: Meets upcoming EU and China regulations for recycled content.

- Validates Trust: Backed by UL 2809 and GRS certifications.

For automotive OEMs and Tier 1 suppliers, transitioning to high-performance PCR PC/ABS is no longer a compromise on quality; it is a strategic upgrade for sustainability and market competitiveness. The Ecoblend® series demonstrates that the loop can be closed without sacrificing the drive.

Post time: Feb-03-2026