Executive Summary

The automotive industry stands at a critical juncture where the definition of vehicle quality has fundamentally expanded. No longer defined solely by horsepower, fuel efficiency, or exterior aesthetics, “quality” in the modern automotive context is increasingly determined by the sensory and physiological experience of the cabin. Central to this experience is Vehicle Interior Air Quality (VIAQ). As regulatory bodies in major markets—most notably China and Europe—tighten restrictions on Volatile Organic Compounds (VOCs), and as consumer awareness regarding “Sick Car Syndrome” grows, Original Equipment Manufacturers (OEMs) face an unprecedented engineering challenge. They must eliminate hazardous emissions and unpleasant odors without compromising the mechanical integrity, safety, or cost-effectiveness of interior components.

This comprehensive research report provides an exhaustive technical analysis of the strategies required to navigate this complex landscape. It focuses on the critical role of advanced engineering thermoplastics, specifically investigating the breakthrough C-Clear® Ultra-Low Emission technology developed by Shanghai Kumho Sunny Plastics. By synthesizing data from global standards (VDA, ISO, GB/T), chemical degradation mechanisms of Polycarbonate/Acrylonitrile Butadiene Styrene (PC/ABS) alloys, and real-world validation cases from premium OEMs like Volvo Cars, this document serves as a definitive guide for materials engineers, procurement executives, and sustainability officers. It elucidates how the adoption of ultra-low emission materials is not merely a compliance activity but a strategic lever for brand differentiation in the era of the “Health-Conscious Cabin.”

Part I: The Global Imperative for Clean Automotive Interiors

1.1 The Paradigm Shift: From “New Car Smell” to Health Risk

For decades, the distinct aroma of a new vehicle—a complex cocktail of outgassing solvents, adhesives, plasticizers, and unreacted monomers—was marketed as a feature, a sensory confirmation of “newness” and luxury. This perception has been radically inverted. Modern toxicological research and shifting consumer demographics have reclassified the “new car smell” as a potential health hazard, comparable to “Sick Building Syndrome.”

The confined volume of a vehicle cabin (typically 2.5 to 3.5 cubic meters) creates a unique micro-environment. Unlike a building, a vehicle is subjected to extreme thermal cycling. Under direct solar irradiation (solar load), dashboard surface temperatures can exceed 100°C, and cabin air temperatures can surpass 60°C. These conditions exponentially accelerate the volatilization of organic compounds from interior trim materials. Research indicates that VOC concentrations in a closed vehicle parked in the sun can exceed safe residential indoor air limits by factors of 10 to 50.

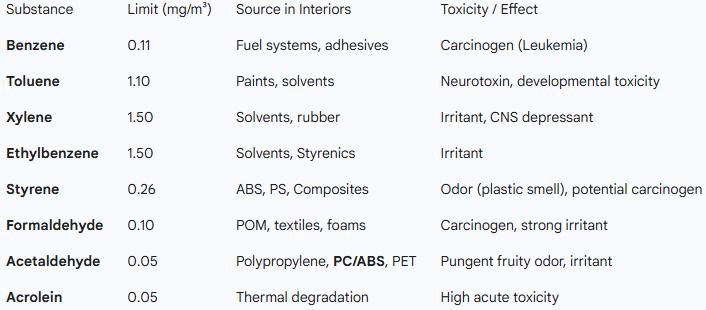

The compounds of primary concern include the BTXS group (Benzene, Toluene, Xylene, Styrene) and low-molecular-weight aldehydes (Formaldehyde, Acetaldehyde, Acrolein). Benzene and Formaldehyde are classified as Group 1 carcinogens by the IARC (International Agency for Research on Cancer). Styrene and Acetaldehyde are potent respiratory irritants and probable carcinogens that also possess low odor detection thresholds, making them dual threats to health and comfort.

1.2 The “Health-Economy” Driver in Asian Markets

The pressure to improve VIAQ is most intense in Asia, which now represents the world’s largest automotive market. In China, South Korea, and Japan, consumer sensitivity to chemical odors is significantly higher than in Western markets. J.D. Power Initial Quality Studies (IQS) in China consistently rank “unpleasant interior smell” as the number one consumer complaint, frequently surpassing engine noise, fuel consumption, or transmission issues.

This “zero-tolerance” consumer attitude has direct economic consequences. A vehicle model that develops a reputation for “bad smell” can suffer immediate sales collapse and long-term brand damage. Consequently, OEMs operating in these regions—including global giants like Volkswagen, GM, and Toyota, as well as domestic leaders—have had to re-engineer their supply chains. They are moving away from treating VIAQ as a “regional requirement” and adopting it as a global baseline to reduce manufacturing complexity.

1.3 The Economic and Operational Risks of Non-Compliance

The cost of non-compliance has escalated from simple customer dissatisfaction to substantial financial liability and operational disruption.

- Mandatory Recalls: The transition of China’s GB/T 27630 from a guideline to a mandatory standard introduces the risk of government-enforced recalls for vehicles exceeding emission limits. The cost of replacing dashboard carriers or door panels in thousands of delivered vehicles is astronomical.

- Supply Chain Deselection: Tier 1 suppliers (producing instrument panels, door trims, center consoles) are increasingly required to provide “Emission Data Sheets” alongside mechanical property data. Suppliers unable to certify materials against VDA or ISO emission standards are being systematically removed from Approved Vendor Lists (AVLs).

- Delay to Market: ”Odor failures” late in the vehicle development cycle are notorious for causing launch delays. If a pre-production vehicle fails a “Nose Team” evaluation, the root cause analysis and material resourcing can delay Start of Production (SOP) by months, costing millions in lost opportunity.

Part II: Decoding the Regulatory Matrix

Navigating VIAQ compliance requires mastering a fragmented landscape of national regulations, industry association standards, and OEM-specific requirements. While there is a trend toward harmonization via ISO/UNECE, significant regional differences remain in testing methodologies and limit values.

2.1 The “Iron Standard”: Volvo’s Approach

Volvo Cars is widely recognized as the global benchmark for interior air quality, integrating it into their brand promise of “Safety” and “Care for People.” Volvo’s internal standards are often stricter than national regulations, effectively serving as a “Super-Standard.”

- Volvo STD 1027, 2729 (Odor): This standard dictates the olfactory assessment of interior materials. Volvo utilizes an “Odor Panel” or “Nose Team” trained to detect not just intensity but “hedonic tone” (pleasantness/unpleasantness). The requirement is typically a rating of < 3.0 on a VDA scale, meaning the odor must be “perceptible but not disturbing.”

- Volvo STD 1027, 2714 (Organic Emissions): This specifies quantitative limits for specific substances. Notably, Volvo places extreme restrictions on sensitizing agents and allergens, requiring materials to be “allergy-tested.”

- The “Clean Zone” Philosophy: Volvo’s Clean Zone Interior Package (CZIP) includes active monitoring of incoming air, but relies fundamentally on the passive reduction of emissions from interior materials. A material that meets Volvo specifications is widely considered “globally compliant” for any other OEM, including BMW, Audi, and Mercedes-Benz.

2.2 Deep Dive: China GB/T 27630

The GB/T 27630 “Guideline for Air Quality Assessment of Passenger Car” is the most critical regulatory document for the global automotive industry today due to the sheer size of the Chinese market. It focuses on eight specific “priority pollutants.”

Table 1: Concentration limits for the “China 8″ substances under GB/T 27630. Note the extremely low limit for Acetaldehyde (0.05 mg/m³), which poses a specific challenge for Polycarbonate alloys.

The standard measures the concentration in the whole vehicle air. However, to meet this, OEMs cascade the requirements down to the component and material level, often applying a safety factor of 10x or 100x to the raw material limits to account for the cumulative surface area in the cabin.

2.3 The European Methodology: VDA Standards

The German Association of the Automotive Industry (VDA) has established the most scientifically rigorous testing protocols, which have been adopted by European OEMs and are increasingly used as the technical basis for global standards.

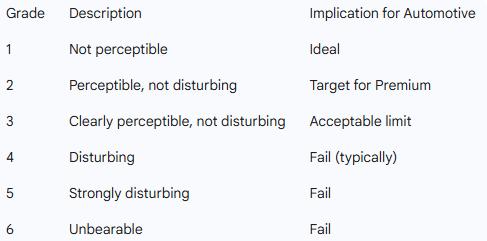

2.3.1 VDA 270: Determination of Odor Characteristics

This is a sensory evaluation method. While subjective, it is critical because the human nose is often more sensitive than Gas Chromatography-Mass Spectrometry (GC-MS) for certain sulfur or amine compounds.

- Procedure: A defined mass/volume of material is placed in an odor-neutral glass jar.

- Conditioning: Variant 2 (typical for trim parts) involves heating to 80°C for 2 hours.

- Evaluation: A panel of at least three trained testers rates the smell immediately upon opening the jar.

Table 2: VDA 270 Odor Rating Scale. A rating of 3.0 is the typical “Pass/Fail” threshold for interior parts.

2.3.2 VDA 278: Thermal Desorption Analysis

VDA 278 is widely considered the “Gold Standard” for material characterization. Unlike headspace methods (VDA 277) that only analyze the air above the sample, VDA 278 uses thermal desorption to strip volatiles directly from the material matrix. It provides two distinct values:

- VOC Value (90°C/30 min): Measures highly volatile compounds (up to n-C20). Reported in toluene equivalents (µg/g).

- FOG Value (120°C/60 min): Measures semi-volatile organic compounds (n-C16 to n-C32) responsible for windshield fogging. Reported in hexadecane equivalents (µg/g).

This method is crucial for identifying the “chemical fingerprint” of emissions, allowing engineers to pinpoint exactly which additive or monomer is causing a failure.

2.4 ISO 12219: The Harmonization Effort

The ISO 12219 series attempts to harmonize the disparate global standards.

- ISO 12219-1: Whole vehicle test chamber method (harmonized with GB/T 27630).

- ISO 12219-2: Bag method for components (widely used in Japan/Korea).

- ISO 12219-3: Micro-scale chamber method (rapid screening).

- ISO 12219-4: Small chamber method.

Despite these efforts, most OEMs continue to enforce their legacy internal standards (like GM’s GMW 15634 or Ford’s WSS-M99P2222) alongside ISO methods, requiring suppliers to maintain versatile testing capabilities.

Part III: The Material Challenge – Polycarbonate/ABS Alloys

3.1 Why PC/ABS is Indispensable

Polycarbonate/Acrylonitrile Butadiene Styrene (PC/ABS) alloy is the dominant material for automotive interiors. It is used in instrument panels, center consoles, pillar trims, glove boxes, and overhead consoles. Its dominance stems from a unique synergy:

- Polycarbonate (PC) provides high heat resistance (HDT), impact strength, and toughness.

- ABS provides flowability (processability), lower cost, and ductility.

- The Alloy offers a balance that neither can achieve alone: high impact strength at low temperatures (critical for airbag deployment) and a high-quality surface finish suitable for painting or direct-molding.

However, this material is also the “Achilles’ Heel” of VIAQ compliance due to its complex chemistry.

3.2 The Chemical Roots of Odor and Emissions

The emission profile of PC/ABS is not singular; it is a complex mixture derived from both constituent polymers and the alloying process.

3.2.1 Residual Monomers from ABS

The ABS component is a terpolymer of Acrylonitrile, Butadiene, and Styrene.

- Styrene: Incomplete polymerization leaves residual styrene monomer. Styrene has a very low odor threshold (0.047 ppm) and a distinctive, sweet, solvent-like smell. It is a major contributor to the “plastic” smell in cars.

- Acrylonitrile: Residual acrylonitrile is highly toxic and regulated strictly.

- Emulsifiers: ABS produced via emulsion polymerization uses surfactants and emulsifiers (e.g., dodecylbenzene sulfonic acid). These residues are difficult to wash out completely and can degrade into malodorous sulfurous compounds upon heating.

3.2.2 The Acetaldehyde Conundrum in Polycarbonate

The most technically difficult challenge in PC/ABS is Acetaldehyde (AA). While typically associated with PET bottles, AA is also a degradation byproduct of Polycarbonate.

- Mechanism: At the high processing temperatures required for PC/ABS (240°C – 270°C), the carbonate linkage in the PC backbone can undergo thermal scission or hydrolysis (if moisture is present). This reaction pathway leads to the formation of acetaldehyde.

- Late-Stage Regeneration: Even if the raw resin is clean, the injection molding process itself—specifically the shear heat generated in the screw and nozzle—can regenerate acetaldehyde.

- Impact: Acetaldehyde has a pungent, fruity/suffocating odor. With the Chinese GB/T 27630 limit set at a vanishingly low 0.05 mg/m³, even trace amounts of AA regeneration in dashboard parts can cause a whole-vehicle failure.

3.2.3 Additive Migration

To achieve properties like UV stability and mold release, various additives are used.

- Lubricants: Low molecular weight waxes can migrate to the surface (blooming) and volatilize.

- Flame Retardants: Phosphate-based flame retardants used in FR-PC/ABS are notorious contributors to SVOCs (FOG) and can deposit oily films on the windshield.

Part IV: The Technological Breakthrough – C-Clear® Ultra-Low Emission Series

Addressing the “PC/ABS Problem” requires more than just better ventilation; it requires a fundamental redesign of the polymer at the molecular and formulation level. Shanghai Kumho Sunny Plastics has pioneered this approach with its C-Clear® Ultra-Low Volatile Series.

4.1 Technological Philosophy: Source Control vs. Post-Treatment

Traditional approaches to reducing VOCs often involved “baking out” parts after molding or using masking agents. C-Clear® adopts a “Source Control” philosophy, eliminating precursors before they become emissions.

Core Technology Pillars:

- Cleaner Polymerization (Bulk vs. Emulsion): Kumho Sunny utilizes ABS synthesized via bulk polymerization for its ultra-low emission grades. Bulk polymerization does not require water, emulsifiers, or coagulants. This eliminates the residual surfactants and salts found in emulsion ABS, removing a primary source of sulfurous odors and fogging agents.

- Ultra-Vacuum Devolatilization: During the compounding (alloying) process, specialized extruders with multi-stage vacuum venting are used. These operate at deep vacuum levels to physically strip residual monomers (styrene, acrylonitrile) and oligomers from the molten polymer.

- Chemical Scavenging Technology: This is the critical innovation for Acetaldehyde control. C-Clear® formulations include proprietary scavenging agents. These reactive additives chemically bond with any acetaldehyde generated during thermal processing, converting it into stable, non-volatile compounds. This effectively neutralizes the “late-stage regeneration” problem during injection molding.

- High-Purity Additive Selection: All lubricants, stabilizers, and antioxidants are screened for volatility. Only high-molecular-weight additives that are thermally stable at 300°C are selected to ensure they do not contribute to VDA 278 FOG values.

4.2 Product Portfolio Analysis

The C-Clear® series is not a single product but a portfolio tailored to specific automotive zones.

4.2.1 Flagship Grade: C-Clear® PC/ABS K8262

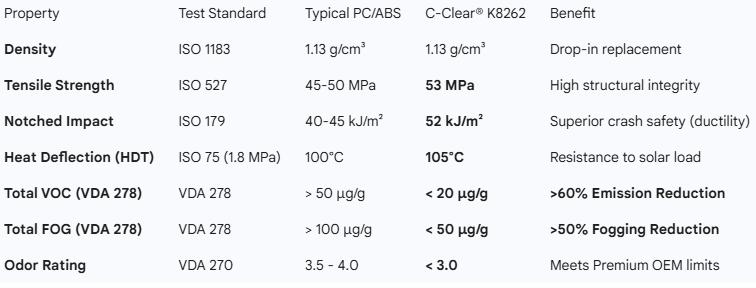

This grade is the “workhorse” for premium interiors, specifically designed to meet high-heat and high-impact requirements while maintaining ultra-low emissions.

Target Applications: Instrument panel structures, center console bodies, air vent housings, glove box doors.

Table 3: Comparative analysis of C-Clear® K8262 versus standard market PC/ABS. Data synthesized from technical datasheets and industry benchmarks.

Insight: The mechanical data shows that K8262 does not sacrifice performance for environmental compliance. In fact, its impact strength (52 kJ/m²) is at the upper end of the spectrum, suggesting high polymer purity aids mechanical toughness.

4.2.2 High-Aesthetics Grade: C-Clear® ABS K7040

For parts that require high surface gloss or deep color without painting (which adds VOCs), K7040 provides a pure ABS solution.

Target Applications: Door trim panels, pillar covers, seat side shields. Key Features:

- Low Odor: Eliminates the “rubber” smell.

- High Rigidity: Optimized for large, thin-walled parts.

- Paintability: While designed for low VOCs, it retains excellent adhesion for water-based (low VOC) paints if required.

4.2.3 Super-Heat Grade: C-Clear® PC/ABS K8272

Designed for the hottest zones in the interior, such as top-mount demister vents that sit directly under the windshield.

- HDT: 108°C.

- Vicat Softening Point: 126°C.

- Performance: Maintains dimensional stability at extreme temperatures where standard PC/ABS would warp, while limiting the thermal degradation that usually causes emission spikes at these temperatures.

4.3 Competitive Benchmarking

How does C-Clear® stack up against global competitors?

- Vs. Trinseo PULSE™: Trinseo focuses heavily on “lightweighting” (low density) and “low gloss” (aesthetic) properties. While PULSE™ is excellent mechanically, C-Clear® positions itself with a stronger emphasis on the chemical reduction of specific aldehydes, making it potentially more robust for the specific chemical limits of GB/T 27630.

- Vs. Elix Ultra HH: Elix offers ABS/PC blends with very low emissions. However, C-Clear® K8262 (PC/ABS) maintains a higher Polycarbonate content, offering superior impact resistance and heat resistance (HDT 105°C vs. typical ~95°C for ABS-heavy blends), which is crucial for safety-critical dashboard carriers.

- Vs. Generic PC/ABS: Generic grades often use standard emulsion ABS and lack scavenging technology. Their acetaldehyde levels frequently exceed 1.0 µg/g, whereas C-Clear® consistently targets <0.1 µg/g, offering a safety margin for OEMs.

Part V: Engineering Success – Application and Processing

Adopting a low-VOC material is only half the battle. The injection molding process introduces thermal and shear history that can degrade the polymer and generate new emissions. Achieving the “Volvo Standard” requires a holistic approach to processing.

5.1 Case Study: The Volvo Experience

The research confirms that C-Clear® materials have been successfully applied to Volvo vehicles. This is a definitive validation.

Context: Volvo’s internal standard (STD 1027, 2729) for odor is notoriously difficult. A “Fail” (Grade > 3.0) from the Volvo Nose Team halts production. Application: C-Clear® K8262 was utilized in Air Outlet Housings and Center Console components. Challenges: These parts have complex geometries with ribs and grills (high shear potential) and are located high in the instrument panel (high solar heat load). Outcome:

- Odor: Achieved consistent ratings of < 3.0.

- Chemicals: Passed STD 1027, 2714 limits for formaldehyde and acetaldehyde.

- Aesthetics: High surface quality allowed for the elimination of soft-touch paint in some areas, further reducing the total part VOC contribution.

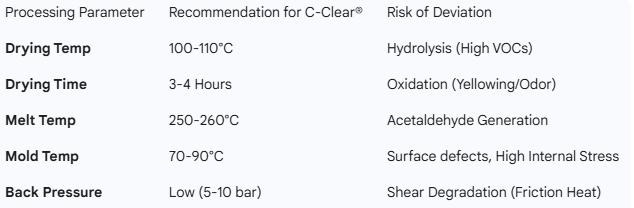

5.2 Processing Guidelines for Low-VOC Retention

To replicate this success, processors must adhere to strict “Low Emission Molding” protocols.

5.2.1 Moisture Control (The Hydrolysis Factor)

Polycarbonate is hygroscopic. Moisture at processing temperatures causes hydrolysis, splitting the polymer chain and releasing phenol and bisphenol-A derivatives, and facilitating acetaldehyde formation.

- Guideline: Drying is non-negotiable.

- Equipment: Dehumidifying dryers (Desiccant) must be used. Hot air dryers are insufficient.

- Target: Moisture content < 0.02% at the throat of the machine.

- Parameters: 100°C – 110°C for 3 to 4 hours. Over-drying (time) can cause thermal oxidation; under-drying causes hydrolysis.

5.2.2 Thermal Management (The Acetaldehyde Factor)

Acetaldehyde generation is exponentially related to temperature and residence time.

- Melt Temperature: Keep between 240°C and 260°C. Never exceed 270°C for K8262. Every 10°C increase above 260°C can double the acetaldehyde generation rate.

- Residence Time: Minimize the time the plastic sits in the barrel. Ideal usage is 40-80% of barrel capacity per shot. If residence time exceeds 5 minutes, purge and restart.

- Screw Speed: Use moderate screw speeds and low back pressure (5-10 bar). High friction creates uncontrolled shear heat, degrading the material even if the barrel heaters are set low.

Table 4: Optimal Processing Window for minimizing VOC generation in C-Clear® PC/ABS.

5.2.3 Tooling and Venting

- Venting: ”Diesel Effect” (compressed gas burning) generates char and acrid smoke/odor. Molds must have generous venting at the end of fill. Vents should be 0.025-0.05 mm deep.

- Gate Design: Avoid pin-point gates that cause extremely high shear rates. Fan or edge gates are preferred for low-stress filling.

- Mold Release: Do not use external mold release sprays. These are often solvent-based and will immediately cause a VDA 278 FOG failure. The C-Clear® resin contains an internal lubricant package sufficient for release from polished molds.

Part VI: Future Horizons

6.1 Sustainability and Recycled Low-VOC Materials

The next frontier in VIAQ is the intersection with the Circular Economy. OEMs are demanding significant Post-Consumer Recycled (PCR) content (e.g., 25-30% by 2030).

- The Conflict: PCR materials, derived from electronic waste or bottles, inherently carry contamination (labels, glues, degraded polymer) that results in poor odor and high VOCs.

- The Solution: Kumho Sunny and other leaders are developing “PCR + Low VOC” technologies. This involves applying the C-Clear® stripping and scavenging technology to the recycled feedstream. By super-cleaning the PCR source and combining it with the high-purity virgin base, it is possible to achieve “Green & Clean” materials—sustainable plastics that still pass the Volvo smell test.

6.2 The Autonomous Cabin as a Living Space

As the industry moves toward Level 4/5 Autonomous Driving (AD), the vehicle cabin transforms from a cockpit into a mobile lounge or office.

- Implication: Occupants will engage in non-driving activities (reading, sleeping), increasing their awareness of the environment. The tolerance for odor will drop to zero.

- Active vs. Passive: While “Active” purification (HEPA filters, ionizers) will be standard, “Passive” material purity will be the foundation. We expect future standards to move beyond “Non-Toxic” to “Wellness Promoting,” potentially requiring materials that are not just neutral, but actively anti-microbial and hypoallergenic.

6.3 Euro 7 and Non-Exhaust Emissions

While Euro 7 currently focuses on tailpipe, brake, and tire emissions, the regulatory trajectory clearly points toward a “Whole Vehicle Life Cycle” assessment. It is anticipated that future iterations of EU regulations will formalize interior air quality limits (currently voluntary or national) into the type-approval process for all vehicles sold in the EU, unifying the disparate VDA and ISO standards into a single, mandatory legal framework similar to GB/T 27630.

Conclusion

The era of regarding interior materials solely as structural or aesthetic components is over. In the modern automotive landscape, plastics are active chemical constituents of the passenger environment. Meeting strict VIAQ standards—particularly the stringent requirements of China’s GB/T 27630 and the high expectations of premium OEMs like Volvo—requires a shift from reactive testing to proactive material engineering.

The C-Clear® Ultra-Low Emission Series represents a proven solution to this challenge. By leveraging high-purity polymerization, vacuum devolatilization, and advanced scavenger chemistry, it breaks the traditional trade-off between mechanical performance and chemical purity.

For Automotive Engineers and Procurement Leaders:

- Specify with Precision: Move beyond generic “PC/ABS” callouts. Specify “Low-VOC / Low-Odor” grades with defined VDA 270/278 limits on the drawing.

- Validate the Process: Recognize that a low-VOC resin can become a high-VOC part if processed poorly. Mandate “Low Emission Molding” parameters.

- Choose Proven Partners: Prioritize suppliers who can demonstrate success with the industry’s toughest critics (e.g., Volvo) and who offer the technical depth to understand the chemistry of emissions, not just the mechanics of molding.

By adopting these advanced material solutions, OEMs can safeguard their brand reputation, ensure global regulatory compliance, and deliver the superior, healthy cabin experience that defines the next generation of mobility.

Post time: Feb-03-2026