Balancing Hydrolytic Stability, Thin-Wall V-0 Performance, and Chemical Resistance in High-Voltage Systems

Author: Principal Material Scientist, Kumho Sunny R&D Center Category: EV Battery Systems / Flame Retardancy / Polymer Chemistry Read Time: 12 Minutes

Abstract

The electrification of the automotive powertrain has shifted material requirements from “Heat & Oil Resistance” (Internal Combustion) to “Electrical Safety & Chemical Stability” (EV). Specifically, Battery Module Housings, Cell Spacers, and High-Voltage Connectors require a unique balance of properties that standard commodity plastics cannot meet. This technical paper provides a selection framework for Flame Retardant (FR) PC/ABS, analyzing the critical trade-offs between UL94 V-0 ratings, Hydrolysis Resistance (PCT aging), and Environmental Stress Cracking Resistance (ESCR) against liquid coolants. We present validation data based on UL746B and GMW3059 to guide engineers in selecting the correct grade for 800V architectures.

1. The Engineering Challenge: The “Triangle of Death”

Selecting a plastic for battery components involves navigating three conflicting requirements. We call this the “Triangle of Death” for polymer formulation:

- High Flame Retardancy: Achieving UL94 V-0 at thin gauges (0.75mm – 1.5mm) to maximize energy density.

- High Impact Strength: Surviving drop tests and crash loads (UN 38.3).

- High Flow: Filling complex, thin-walled geometries without stress concentration.

Adding Flame Retardants (usually Phosphate-based for PC/ABS) inherently degrades impact strength and flow. Furthermore, the environment inside a battery pack—high heat (60celsius – 80celsius) and humidity—triggers the primary failure mode of Polycarbonate: Hydrolysis.

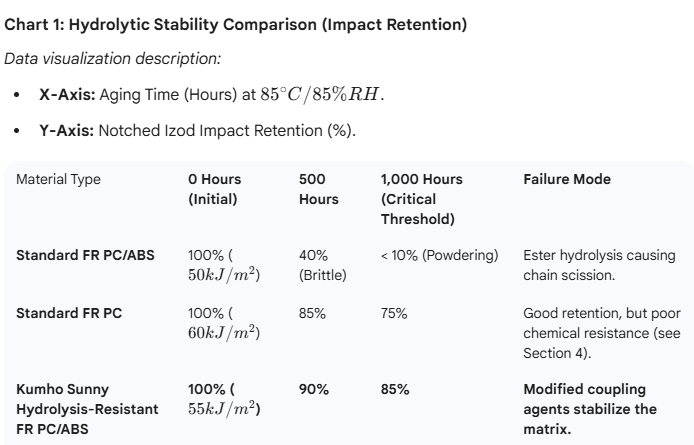

2. Hydrolysis Resistance: The Hidden Failure Mode

Standard FR PC/ABS is susceptible to ester bond cleavage when exposed to moisture and heat. Over time, this causes a catastrophic loss of molecular weight and mechanical properties.

The Test: ”85/85 Test” (85celsius at 85% Relative Humidity) or the Pressure Cooker Test (PCT).

Engineering Guideline: For battery packs with a warranty of 8-10 years, selecting a material that fails the 1,000-hour 85/85 test is a direct risk to structural integrity.

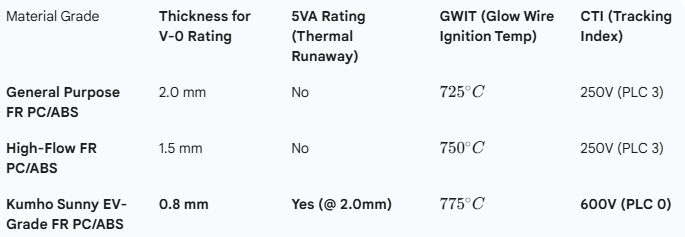

3. Thin-Wall Flame Retardancy: Maximizing Energy Density

In cell-to-pack (CTP) designs, every millimeter of plastic thickness is “dead space” that reduces volumetric energy density. Therefore, engineers are pushing wall thicknesses down from 2.0mm to 1.0mm or even 0.8mm.

Achieving UL94 V-0 at these thicknesses requires a high loading of FR additives (e.g., RDP/BDP). However, excessive additives lead to:

- “Juicing” (Plate-out): Additives migrate to the surface, causing mold fouling and electrical contact issues.

- Reduced CTI (Comparative Tracking Index): Increasing the risk of electrical arcing.

Table 1: UL94 & CTI Performance Matrix

Key Citation: High CTI (PLC 0 or 1) is critical for 800V architectures to prevent tracking paths between busbars. Reference IEC 60112 for test methods.

4. Chemical Resistance (ESCR): The Coolant Risk

Liquid cooling systems (Glycol/Water mixtures) run throughout the battery pack. A microscopic leak should not cause the structural plastic to crack.

PC/ABS is amorphous and generally sensitive to chemicals. Polypropylene (PP) is resistant but lacks the dimensional accuracy for tight tolerance modules.

The Test: ASTM D543 / ISO 22088 (Environmental Stress Cracking Resistance).

- Method: Apply 1.0% strain to the sample, apply coolant (Ethylene Glycol), wait 168 hours.

Results:

- Standard PC/ABS: Cracks within 24 hours (Critical Failure).

- Kumho Sunny “Stress-Crack Resistant” FR PC/ABS: No cracking after 168 hours.

- Mechanism: Optimized Acrylonitrile (AN) content in the ABS phase acts as a chemical barrier, while maintaining the heat resistance of the PC phase.

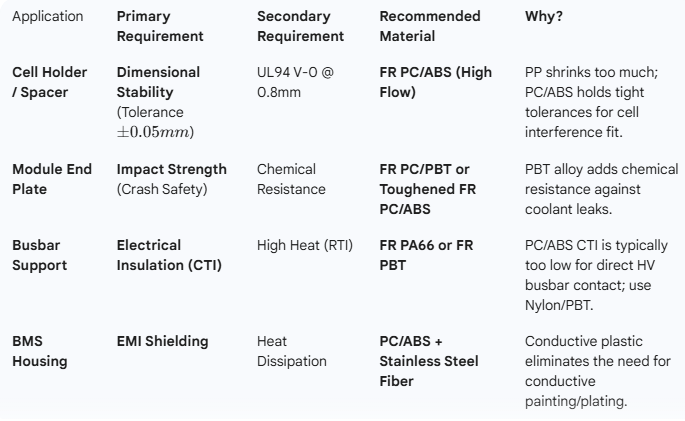

5. Comparison: Which Material for Which Component?

Not all battery components are created equal. Below is a selection guide based on functional requirements.

Table 2: Application-Specific Material Selection

6. Manufacturing: Spiral Flow and Processability

For large, thin-walled parts (like module top covers), melt flow length determines the clamping tonnage and injection pressure.

Data: Spiral Flow Length

- Conditions: 260celsius, Melt Temp, 80celsius, Mold Temp, 1000 bar Injection Pressure, 2.0mm channel.

- Standard FR PC/ABS: 45 cm flow length.

- Kumho Sunny “Thin-Wall” FR PC/ABS: 65 cm flow length.

Implication: The high-flow grade allows for:

- Lower injection pressures.

- More cavities per mold (higher productivity).

- Filling 1.0mm walls without “short shots.”

7. Conclusion: The “Spec-In” Checklist

Selecting the right FR PC/ABS is no longer just about checking the datasheet for “UL94 V-0.” In the era of EVs, the material must pass a gauntlet of reliability tests.

Engineers should request the following data package from suppliers:

- Yellow Card: Verify RTI (Elec/Imp/Str) and V-0 thickness.

- Hydrolysis Curve: Impact retention after 1,000h @ 85/85.

- ESCR Report: Resistance to the specific coolant used (e.g., G48, G30).

- C-S-E (Charpy-Spiral-Elongation) Map: To understand the processing window.

At Kumho Sunny, our HAC and PC/ABS Alloy Series have been formulated specifically to survive the “Triangle of Death,” offering a drop-in solution for Tier 1 battery system manufacturers.

Post time: Jan-21-2026