By: The Advanced Materials Engineering Team Filed under: Automotive Design, Sustainable Manufacturing, CMF Trends

- Visual Masking: By using specialized textures (like the “Bare Sand Pottery” or “Denim Blue” speckled effects), the material visually absorbs the inherent impurities of PCR.

- The Result: A part that is made of recycled plastic and requires no painting.

- Data Point: Using a material like Ecoblend® PCR ABS reduces carbon emissions significantly (e.g., ER2100 is 100% PCR ABS ), and skipping the paint process reduces the carbon footprint further.

Part 5: Case Studies & Applications

To understand the viability of this technology, we look at real-world applications verified by Kumho Sunny.

Case A: The “Ceramic” Look for Consumer Electronics & Interiors

- Product: Lenovo AIO 520 Computer Shell.

- Material: White PCR ABS with Colorful-in technology.

- The Innovation: Traditionally, achieving a pure white, high-gloss finish on recycled plastic was impossible due to black spot contamination. Kumho Sunny used a “speckled” natural aesthetic (mimicking natural mica or stone) to turn the defects into a design feature.

- Automotive Application: This exact logic is now being applied to EV interiors, where “Tech-Natural” aesthetics (replacing piano black with stone-like textures) are becoming a major trend.

Case B: Structural & Weatherable Exteriors

- Product: Exterior Pillar Trim and Mirror Housings.

- Material: ASA or PC/ASA (Weather resistant).

- The Look: High-gloss Piano Black or Metallic Silver.

- Benefit: Kumho Sunny’s formulations offer “special color + texture” that realize the visual expression of the material without the peeling risks associated with painting or plating.

Case C: The “Hiding” Texture

- Concept: “Smallfry Seafood Restaurant” Design Trend.

- Material: PCR ABS.

- Texture: “Dynamic Diamond”.

- Relevance: In automotive door panels or lower bumper trims, using a heavy texture like Dynamic Diamond allows the use of lower-cost, high-percentage PCR materials because the texture hides sink marks and flow lines that would be visible on a smooth painted surface.

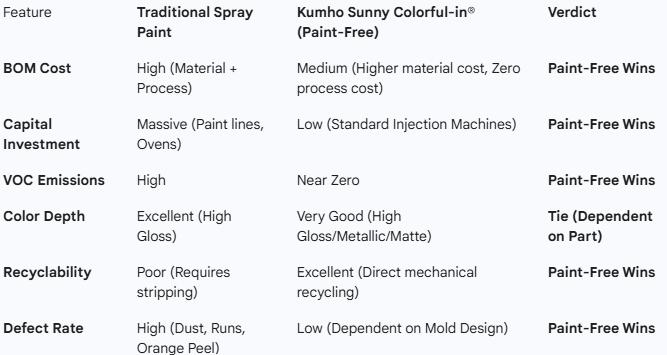

Conclusion: Which is Best for the Future?

The verdict depends on the application, but the trajectory is clear.

Traditional Spray Painting will likely remain for the Body in White (BIW)—the main metal skin of the car—for the next decade due to the sheer difficulty of color-matching metal and plastic perfectly across large surface areas.

However, for Automotive Trim, Bumpers, Grilles, Spoilers, and Interiors, Paint-Free Plastic (Colorful-in®) is the superior solution for the future.

Why?

- ESG Compliance: It is the only way to make PCR plastics visually acceptable for visible parts.

- Cost: It removes the most expensive step in manufacturing.

- Aesthetics: It moves away from the “cold” look of paint toward “warm,” textured, and natural finishes that define the modern Electric Vehicle cabin.

As companies like Kumho Sunny continue to refine the flow properties and aEEEEEEEEEesthetic depth of these materials, we are entering an era where the “Paint Shop” may eventually become a relic of the past.

Post time: Dec-22-2025