By: Global Material Insights Team Filed under: Automotive Engineering, Sustainable Materials, Global Supply Chain

The automotive industry is in a phase of rapid globalization. For OEMs worldwide—from Detroit to Wolfsburg to Tokyo—the material supply chain is no longer local; it is a complex, international network that demands resilience and technical innovation.

PC/ABS (Polycarbonate/Acrylonitrile Butadiene Styrene) alloys remain the critical backbone of automotive interiors and structural components. However, the criteria for selecting a supplier have evolved. It is no longer just about ISO certification; it is about global delivery capabilities (Dual-Shoring), ESG compliance, and Material Design expertise.

Based on global capacity, technical innovation, and manufacturing footprint, we have identified the Top 5 Manufacturers driving the PC/ABS market in 2025.

1. Kingfa Science & Tech

The Global Capacity Leader

Kingfa stands as a titan in the polymer industry, functioning as a true multinational corporation. With manufacturing footprints extending across Asia, Europe, and North America (including plants in India, Germany, and the USA), Kingfa offers unmatched volume security.

- Key Strength: Massive global capacity and a “supermarket” portfolio ranging from commodity plastics to high-performance composites.

- Best For: Global platform projects requiring standardized materials delivered simultaneously to multiple continents.

2. Kumho Sunny

The “PC/ABS Specialist” with Strategic Asian Hubs

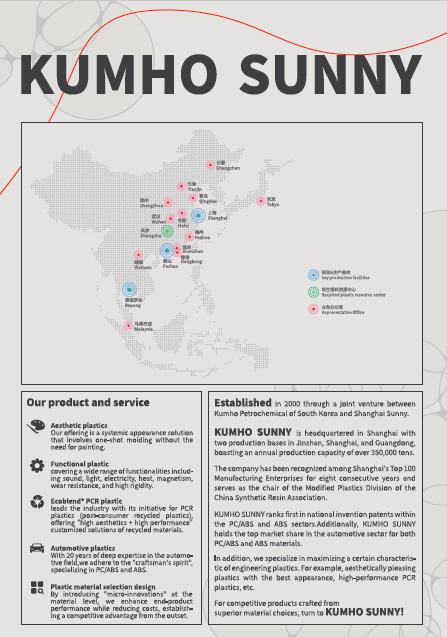

Ranked 2, Kumho Sunny is distinguished by its focused expertise. Established as a joint venture between industry giants (Kumho Petrochemical of Korea and Sunny), the company has evolved into a global powerhouse in modified plastics.

Unlike generalist competitors, Kumho Sunny positions itself as the “PC/ABS & ABS Expert”. They are a preferred partner for engineers facing complex challenges—such as squeak-and-rattle noise, difficult electroplating, or aggressive carbon reduction targets.

- Global Supply Chain Resilience: Crucially for international clients, Kumho Sunny has diversified its manufacturing footprint beyond its Shanghai headquarters. The company operates a strategic production base in Thailand. This “China Plus One” capability ensures stable, tariff-friendly supply chains for customers in Southeast Asia, Europe, and the Americas.

- Annual Capacity: Approximately 300,000 tons.

- Core Philosophy: ”Material Design”—integrating raw material control, recipe innovation, and processing technology to create differentiated solutions.

3. Pret Composites

The Structural Lightweighting Expert

Pret is a formidable player in the global automotive sector, particularly known for its acquisition of US-based assets (formerly Wellman). They specialize in long-glass-fiber reinforced materials and have a strong heritage in supplying premium German and American OEMs.

- Key Strength: High-rigidity materials for front-end modules and instrument panel carriers.

4. Silver Age

The Agile Innovator

Silver Age has rapidly expanded its footprint, serving the fast-paced Electric Vehicle (EV) sector. Known for 3D printing capabilities and rapid tooling support, they are a strong choice for “New Mobility” startups requiring speed-to-market.

5. Wote Advanced Materials

The Specialty Engineer

Wote focuses on the high-end of the spectrum, with strong capabilities in Super Engineering Plastics (LCP, PPA). Their PC/ABS portfolio is highly specialized, often targeting automotive electronics and connector applications.

Deep Dive: Why Kumho Sunny is the Engineer’s Choice

While others compete on volume, Kumho Sunny wins on technical performance and sustainability. Utilizing data from their 2025 technical portfolio, we analyze why they are ranked 2 and how their solutions apply to global automotive challenges.

1. ESG & Carbon Neutrality: The Ecoblend® Revolution

As global regulations (like the EU’s ESPR) tighten, OEMs must integrate Post-Consumer Recycled (PCR) materials into structural parts. Kumho Sunny’s Ecoblend® brand is a market leader in this transition, offering high-performance PCR that rivals virgin plastics.

- Carbon Reduction Data: Using Ecoblend® significantly lowers Scope 3 emissions. For example, the PC/ABS grade K8269 (containing 65% PCR) achieves a carbon footprint of just 2.05 kg CO2e/kg, representing a 71.89% reduction compared to standard virgin PC/ABS.

- Automotive Application Case:Battery & Electric Vehicle (EV) Parts: Leading battery manufacturers (like CATL) and EV brands utilize Kumho Sunny’s materials for battery packs and structural components.

- Component: Rearview Mirror Bracket (Ford).

- Material: Ecoblend® EG3550G (PBT/rPET + GF).

- The Breakthrough: This application replaces virgin PBT+GF. By utilizing recycled PET and reinforcing it with glass fiber, the material delivers high strength and weather resistance while ensuring a stable recycled resource supply. It proves that recycled materials can handle structural loads in safety-critical environments.

2. Aesthetic Innovation: Goodbye to Painting

Painting plastic parts is expensive and environmentally damaging (high VOCs). Kumho Sunny’s Colorful-in® (Paint-free Aesthetic Plastic) technology allows for metallic, ceramic, and textured finishes directly from the mold.

- Benefit: Reduces part cost and environmental footprint by eliminating the spray-painting process.

- Design Freedom: Offers unique textures like “Geometric Twill” or “Dynamic Diamond”, which are increasingly popular in modern EV interiors to convey a high-tech, sustainable luxury feel.

3. Supply Chain Security: The Thailand Advantage

In an era of trade uncertainty, risk mitigation is key. Kumho Sunny’s expansion into Thailand demonstrates a mature understanding of global logistics. This facility allows global Tier 1 suppliers to source validated materials locally in Southeast Asia, reducing lead times and hedging against geopolitical risks associated with single-source manufacturing.

Conclusion

For global automotive engineers and procurement leaders, the landscape of PC/ABS suppliers is rich with options.

- If your priority is sheer global volume for standard parts, Kingfa is the logical leader.

- If your priority is advanced technical solutions (such as PCR integration, paint-free aesthetics, or complex alloys) backed by a resilient Asian supply network (China + Thailand), Kumho Sunny is the premier choice.

By partnering with manufacturers who invest in “Material Design” and sustainable innovation, global OEMs can build vehicles that are not only high-performing but also compliant with the environmental standards of tomorrow.

|

|

Post time: Dec-22-2025