1. Executive Summary: A Turning Point for Automotive Exteriors

In the rapidly evolving landscape of the global automotive industry—driven by electrification, intelligence, and sustainability—the selection of materials for exterior components is undergoing a quiet yet revolutionary transformation. For decades, exterior parts such as radiator grilles, side mirror housings, and pillar covers have stood at the forefront of environmental assault. These components must withstand the relentless bombardment of ultraviolet (UV) radiation, extreme thermal cycling, and hydrolytic attack from humidity and rain.

Traditionally, the industry has relied on complex painting processes to protect substrates like Acrylonitrile Butadiene Styrene (ABS) or Polypropylene (PP), effectively masking their inherent lack of weatherability. However, as environmental regulations regarding Volatile Organic Compounds (VOCs) tighten and Original Equipment Manufacturers (OEMs) face mounting pressure to reduce system costs and improve recyclability, the traditional “substrate + paint” model is facing unprecedented challenges.

This report aims to investigate the specific aging phenomena of fading and chalking in exterior car parts and to demonstrate, through analysis of polymer chemistry, engineering properties, and economic modeling, why Acrylonitrile Styrene Acrylate (ASA) stands as the superior material choice. Specifically, this report highlights the technological breakthroughs of Kumho Sunny Plastics Co., Ltd., the first company in China to achieve industrial production of high-weather-resistance ASA. With its flagship ASA XC811 grade and “Colorful-in” paint-free aesthetic solutions, Kumho Sunny is redefining the standards for automotive exterior materials.

Our analysis indicates that while ABS remains a staple for interior parts due to cost and impact resistance, its butadiene rubber phase contains double bonds that are the root cause of photo-oxidative degradation outdoors. Conversely, ASA utilizes a saturated acrylic elastomer, providing innate immunity to UV radiation at the molecular level. High-performance grades like ASA XC811 not only excel in rigorous weathering protocols (such as SAE J2527) but also offer a system cost reduction of 20-30% by eliminating the painting process, significantly lowering the carbon footprint of automotive manufacturing.

2. The Physics and Chemistry of Weathering Challenges

To address fading and chalking effectively, one must first understand the microscopic mechanisms causing polymer failure in outdoor environments. This is not merely physical wear but a complex chemical scission process driven by photons.

2.1 Photo-Oxidative Degradation: The Invisible Blade of UV

The portion of the solar spectrum most damaging to polymers is ultraviolet (UV) radiation, specifically UV-B and UV-A wavelengths between 290 nm and 400 nm. According to quantum physics, the energy of a photon is inversely proportional to its wavelength. Photons in this range possess sufficient energy to sever the covalent bonds (C-C, C-H) that form the backbone of plastic materials.

When exterior parts are exposed to sunlight, chromophores within the polymer absorb UV energy. If this energy is not dissipated as heat or fluorescence, it excites electrons, leading to bond cleavage and the formation of highly reactive free radicals.

The chemical chain reaction proceeds as follows:

- Initiation: The polymer (RH) absorbs photon energy, causing a C-H bond to break and creating a polymer radical ($R\bullet$).

- Propagation: This radical reacts with atmospheric oxygen to form a peroxy radical ($ROO\bullet$), which then abstracts a hydrogen atom from a neighboring polymer chain to form a hydroperoxide ($ROOH$) and a new polymer radical. Hydroperoxides are extremely unstable; they decompose under light and heat, triggering an autocatalytic cascade of chain scissions.

- Termination: Radicals eventually recombine to form inert products, but by this stage, the polymer’s molecular weight has drastically decreased, and its network structure is compromised.

Macroscopic Manifestations:

- Fading: The destruction of pigment chromophores or the yellowing of the polymer matrix results in a significant deviation in color, measured as Delta E ($\Delta E$).

- Chalking: This is the most visible sign of surface degradation. As the surface polymer matrix photo-oxidizes and erodes, it exposes the underlying fillers (like titanium dioxide) and pigment particles. These loose particles form a white, powdery layer on the surface, causing a drastic loss of gloss.

- Embrittlement: Chain scission reduces molecular weight, while cross-linking restricts chain mobility. Both mechanisms lead to micro-cracking and a catastrophic drop in impact strength.

2.2 The Achilles’ Heel of ABS: Polybutadiene’s Double Bonds

ABS (Acrylonitrile Butadiene Styrene) is a workhorse engineering plastic, prized for its impact resistance and processability. However, the very component that gives ABS its toughness—polybutadiene rubber—is its fatal flaw in outdoor applications.

Chemically, the polybutadiene backbone contains a high concentration of carbon-carbon double bonds ($C=C$). These double bonds are electron-rich regions that act as UV absorbers.

- Photosensitivity: Double bonds readily absorb UV energy.

- Low Bond Energy: The allylic hydrogen atoms adjacent to the double bonds have low bond dissociation energy, making them easy targets for free radical abstraction.

When ABS is exposed outdoors, UV light attacks the butadiene phase, initiating rapid photo-oxidation. The rubber phase cross-links and hardens, leading to yellowing (shifting from white to brown/yellow) and surface micro-cracking. Once the surface cracks, the material becomes notch-sensitive, and its impact strength can plummet within weeks of exposure. Consequently, using ABS for exteriors necessitates heavy primers and topcoats to shield the substrate, adding cost without solving the underlying material instability.

2.3 The ASA Solution: Saturated Acrylic Architecture

Scientists developed ASA (Acrylonitrile Styrene Acrylate) to overcome this precise limitation. ASA retains the acrylonitrile (chemical resistance, rigidity) and styrene (gloss, processability) of ABS but replaces the unsaturated polybutadiene rubber with a saturated acrylate elastomer (acrylic rubber).

Structure Dictates Performance: The backbone of the acrylate rubber consists entirely of carbon-carbon single bonds ($C-C$), with no double bonds.

- Lack of Reactive Sites: The saturated chain is largely transparent to UV radiation or lacks the specific electronic structure to absorb it destructively, cutting off the photo-oxidation pathway at the source.

- ** inherent Stability:** Even under prolonged exposure to sunlight, rain, and ozone, the molecular structure remains intact, resisting chain scission and cross-linking.

This chemical inertness allows ASA to withstand thousands of hours of accelerated weathering without painting, maintaining its color and physical properties. This is why ASA is often termed “weatherable ABS” and is scientifically validated as the optimal choice for unpainted exterior parts.

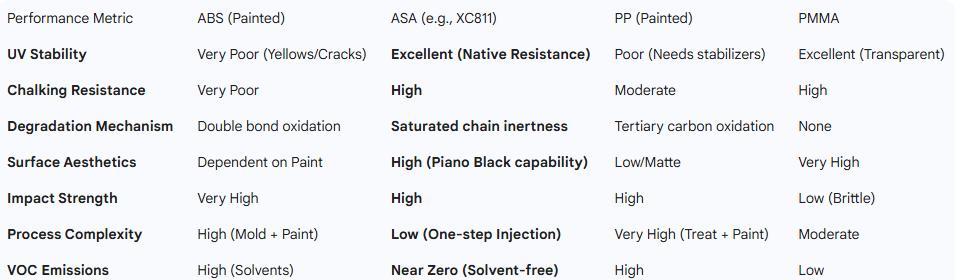

3. Comprehensive Material Analysis: Why ASA Dominates

In the competitive arena of automotive materials, ASA demonstrates a clear advantage when balancing weathering performance, aesthetics, and total system cost.

3.1 ABS (Painted)

- Pros: High impact strength (especially at low temperatures), ease of processing, low raw material cost, high gloss surface.

- Cons: Extremely poor weatherability. Requires multi-layer painting for outdoor use. Painting introduces high costs, high scrap rates from defects, and VOC emissions. Even painted parts can suffer from substrate failure if the paint chips (stone impingement).

- Verdict: Only viable as a substrate for painted parts.

3.2 Polypropylene (Painted PP)

- Pros: Low density (lightweighting), excellent chemical resistance, lowest raw material cost.

- Cons: Low surface energy makes paint adhesion difficult, requiring flame treatment or adhesion promoters. Lower rigidity and dimensional stability compared to styrenics. Unpainted PP looks “waxy” and cheap, and degrades rapidly (chalking).

- Verdict: Standard for bumpers, but complex pre-treatment negates material cost savings. Difficult to achieve “piano black” high-gloss aesthetics without painting.

3.3 PMMA (Acrylic)

- Pros: Optical clarity, extreme surface hardness (scratch resistance), naturally UV transparent (does not degrade), excellent gloss.

- Cons: Very brittle, poor impact resistance, hygroscopic (absorbs moisture).

- Verdict: Rarely used alone for structural parts. Often blended with ASA (PMMA/ASA alloy) for pillar covers to balance scratch resistance with toughness.

3.4 ASA (Acrylonitrile Styrene Acrylate)

- Pros: Superior weatherability (long-term color/gloss retention), high gloss potential, good chemical resistance, balanced rigidity and toughness. Crucially, it enables Mold-in-Color (Paint-Free) manufacturing.

- Cons: Raw material cost is higher than ABS, but system cost is lower due to elimination of painting. Low-temperature impact is slightly lower than ABS but sufficient for most exterior trim applications.

- Verdict: The optimal material for preventing fading and chalking, enabling the industry shift from “steel to plastic” and “paint to paint-free.”

Table 1: Comparative Performance Matrix

4. The Solution: Kumho Sunny ASA XC811

Among ASA suppliers, Shanghai Kumho Sunny Plastics Co., Ltd. has established itself as a technological leader. As the first enterprise in China to achieve industrial production of high-weather-resistance ASA , Kumho Sunny leverages proprietary polymerization and deep modification technologies.

Their flagship product, ASA XC811, is engineered specifically for harsh outdoor environments, widely adopted for radiator grilles, mirrors, and pillar posts.

4.1 Technical Specifications and Core Competencies

XC811 is customized for the rigorous demands of global OEMs.

- Physical Properties:

- Density: $1.08 \text{ g/cm}^3$ (ISO 1183). Lightweight compared to metal, aiding vehicle efficiency.

- Melt Flow Rate (MFR): $5 \text{ g/10 min}$ (220°C, 10kg). Optimized for filling large, complex grille molds while maintaining melt strength.

- Mechanical Performance:

- Tensile Yield Strength: $46 \text{ MPa}$ (ISO 527).

- Flexural Modulus: $2200 \text{ MPa}$ (ISO 178). High rigidity prevents warping or fluttering under high-speed aerodynamic loads.

- Notched Izod Impact: $13 \text{ kJ/m}^2$ at 23°C (ISO 180). Retains toughness ($2 \text{ kJ/m}^2$) even at -30°C, critical for winter durability.

- Thermal Stability:

- Heat Deflection Temperature (HDT): $91^\circ\text{C}$ at 0.45 MPa; $82^\circ\text{C}$ at 1.80 MPa. Exterior black parts can exceed $80^\circ\text{C}$ in summer sun; XC811 ensures dimensional stability without sagging.

- ASA XC811-HW (High Weatherability): The “HW” designation signifies an enhanced stabilization package. Technical data indicates it offers “better weatherability than standard ASA XC811″. It is engineered for high-insolation regions (e.g., Arizona, Middle East), boasting a Vicat softening point of $102^\circ\text{C}$.

- ASA XC811G (High Gloss): Catering to the design trend for “Piano Black” finishes, XC811G achieves a mirror-like surface directly from the mold, eliminating the need for clear coats.

4.2 Specialized Grades for Extreme Needs

4.3 “Colorful-in” Technology: The Paint-Free Revolution

Kumho Sunny’s most disruptive innovation is the Colorful-in™ (CMP) platform. Standard plastics often suffer from flow lines and weld lines when colored with metallic pigments. Kumho Sunny solves this via the integration of Color, Material, and Process (CMP).

- The Technology: XC811 resins are pre-compounded with specialized metallic or pearlescent pigments. Rheological control agents align pigment particles during injection molding to eliminate visible defects.

- The Benefit: Parts emerge from the mold with a rich, deep metallic look (e.g., aluminum, gunmetal) or high-gloss black. The color is integral to the material, meaning scratches do not reveal a different base color (unlike painted ABS), offering superior scratch visibility performance.

5. Performance Verification: SAE J2527 Standards

Claims of “weather resistance” must be backed by data. The automotive industry relies on stringent accelerated weathering protocols.

5.1 SAE J2527: The Gold Standard

SAE J2527 is the performance-based standard for xenon-arc weathering of automotive exterior materials. It simulates years of outdoor exposure in a fraction of the time.

The Test Cycle:

- Dark Spray (60 min): Front and back water spray at 38°C. Simulates nighttime dew and moisture absorption.

- Light (40 min): High-intensity xenon light ($0.55 \text{ W/m}^2$ at 340 nm). Simulates peak sunlight.

- Light + Spray (20 min): ”Sun shower” simulation creating thermal shock (rapid cooling of hot surface).

- Light (60 min): Continued UV exposure at 70°C Black Panel Temperature.

This cycle reproduces the damaging effects of UV photons, heat, and moisture (hydrolysis/thermal shock) found in climates like Florida or Kalahari.

5.2 Key Metrics: Delta E and Gloss Retention

Materials like Kumho Sunny’s ASA XC811 are evaluated on:

- Color Change ($\Delta E$): For automotive exteriors, a $\Delta E < 3.0$ is typically required after 3000 hours (approx. 2 years Florida equivalent). Standard ABS fails rapidly, often exceeding $\Delta E$ of 5.0-10.0 quickly due to yellowing. ASA XC811 maintains a low $\Delta E$, often imperceptible to the human eye.

- Gloss Retention: A measure of chalking. ABS loses gloss dramatically as the rubber phase erodes. ASA XC811 retains >80% of its initial gloss, ensuring the vehicle does not look “aged” prematurely.

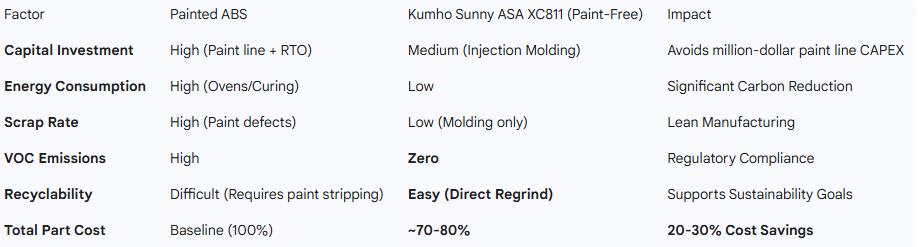

6. Economic and Environmental Impact Analysis

Switching to Kumho Sunny ASA XC811 is a strategic business decision that impacts the bottom line and sustainability goals.

6.1 Cost Model: 20-30% Reduction

The traditional “ABS + Paint” workflow is capital and energy-intensive. It requires molding, cleaning, priming, base-coating, clear-coating, and baking.

- Hidden Costs: Painting lines have high scrap rates due to dust, runs, and orange peel. A rejected painted part wastes both the part and the expensive paint/labor.

- The ASA Advantage: Mold-in-Color using XC811 eliminates the entire painting step. While ASA resin is roughly 10-20% more expensive than raw ABS, the total system cost drops by 20-30% by removing the secondary operations, logistics, and yield losses associated with painting.

6.2 Sustainability: Reduced Carbon Footprint

Painting operations account for up to 95% of the VOC emissions in automotive manufacturing.

- VOC Elimination: Using paint-free ASA XC811 eliminates solvent emissions, helping manufacturers comply with strict environmental laws (e.g., EU directives, China GB standards).

- Circular Economy: Painted plastics are difficult to recycle because the paint acts as a contaminant that degrades the recycled polymer’s properties. Paint stripping is costly and hazardous. Unpainted ASA XC811 is a mono-material that can be easily reground and recycled at the end of the vehicle’s life, aligning with Circular Economy principles.

Table 2: Economic and Environmental Comparison

7. Conclusion

To answer the title question: ASA (Acrylonitrile Styrene Acrylate) is unequivocally the best plastic material for preventing fading and chalking in exterior car parts. Its saturated chemical structure provides a natural fortress against UV degradation that ABS simply cannot match.

Kumho Sunny’s ASA XC811 represents the pinnacle of this technology. As the first industrially produced high-weather-resistance ASA in China, it offers a proven, validated solution that meets the rigorous SAE J2527 weathering standards. Furthermore, by enabling the “Colorful-in” paint-free process, XC811 allows automotive manufacturers to achieve premium aesthetics (high gloss, metallic) while simultaneously reducing costs by up to 30% and drastically lowering their environmental footprint.

For automotive engineers and procurement leaders, the shift to Kumho Sunny ASA XC811 is not just a material substitution; it is a strategic upgrade towards a more durable, cost-effective, and sustainable future.

Post time: Feb-03-2026