A Tribological and Economic Analysis of Mold-in-Color (MIC) Technologies

Author: Senior Product Engineer, Kumho Sunny R&D Center

Category: Exterior Aesthetics / Lightweighting / Sustainable Manufacturing

Read Time: 12 Minutes

Executive Summary

For decades, the “Piano Black” aesthetic—synonymous with premium automotive design—has been achieved almost exclusively through painting ABS or PC/ABS substrates. While effective visually, the painting process is a manufacturing bottleneck, a major source of Volatile Organic Compounds (VOCs), and a significant cost center.

As the automotive industry pivots toward carbon neutrality and cost-efficiency (driven largely by the EV sector’s need to offset battery costs), High Gloss Mold-in-Color (MIC) plastics have emerged as a viable alternative. This technical paper evaluates the material science behind High Gloss PC/ASA and PMMA/ASA alloys, analyzing their ability to meet OEM specifications for weathering (SAE J2527), scratch resistance (ASTM D3363), and jetness (L* < 6$). We demonstrate that with the correct rheological formulation and mold technology, MIC plastics can not only replace paint but offer superior long-term value.

1. The Engineering Challenge: Why “Black” is Not Enough

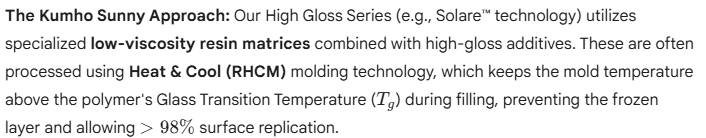

To replace a painted part, the plastic substitute cannot simply be black; it must replicate the depth of image (DOI) and leveling of a clear-coated surface.

In standard injection molding, the replication of the mold surface is inhibited by the “Frozen Layer” effect. As the molten polymer (240-260celsius) contacts the cooler mold wall (60-80celsius), it instantly solidifies. This creates a microscopic “skin” that fails to conform perfectly to the polished tool steel, resulting in micro-texture that scatters light and reduces Gloss Units (GU).

Table 1: Optical Metrics Comparison

2. Weathering Resistance: The Chemistry of Longevity

The primary skepticism regarding unpainted exterior plastics is weathering: “Will it turn gray after two years in Florida?”

Standard ABS (Acrylonitrile Butadiene Styrene) is unsuitable for unpainted exteriors because the Butadiene rubber phase contains double bonds (-C=C-). These bonds are highly reactive to UV radiation, leading to photo-oxidation, chain scission, and the tell-tale “chalking” (whitening) of the surface.

To solve this, we utilize ASA (Acrylonitrile Styrene Acrylate). In ASA, the butadiene rubber is replaced by an acrylic ester rubber. This saturated chemical structure is inherently immune to UV degradation.

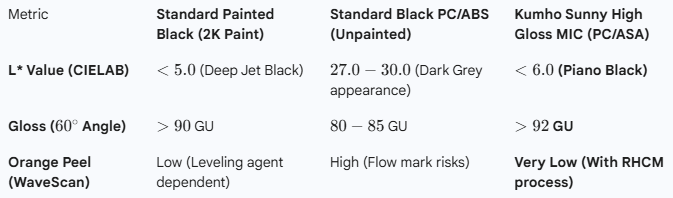

Data Analysis: Accelerated Weathering (SAE J2527)

We subjected test plaques to 3,000 hours of Xenon Arc exposure (simulating ~2-3 years of Florida sunlight) according to SAE J2527 / ISO 4892-2.

Engineering Note: While PMMA offers the best natural UV resistance, it is brittle. Our PC/ASA alloys balance the high heat resistance and impact strength of Polycarbonate (PC) with the UV stability of ASA, meeting GMW 14867 requirements for exterior trim.

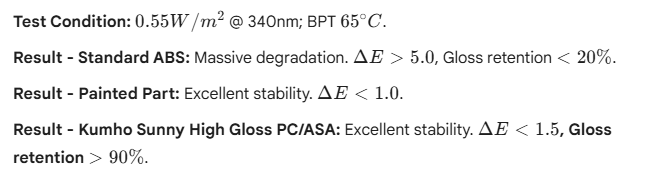

3. Scratch Resistance: Hardness vs. Visibility

A painted surface typically has a pencil hardness of H to 2H (due to the UV-cured clear coat). Unpainted thermoplastics are generally softer. However, the perception of the scratch is what drives warranty claims.

Table 2: Scratch & Mar Resistance Performance

The “Self-Healing” Effect: Unlike paint, which is a brittle layer on top of a substrate, MIC plastics are homogenous. Minor surface mars on high-gloss PC/ASA can often be polished out or reduced via heat gun treatment, whereas a deep scratch in paint requires repainting the entire component.

4. Economic Analysis: The “Total System Cost” Argument

This is the decisive factor for Program Managers. While High Gloss resins carry a premium price per kilogram compared to standard substrates (approx. 30-40% higher), they eliminate the most expensive step in manufacturing: The Paint Shop.

Cost Model Breakdown

Let us analyze the cost structure for a typical C-Pillar Applique.

Scenario A: Painted PC/ABS

- Molding: Standard Resin + Injection.

- Logistics: Transport to Paint Shop (WIP inventory).

- Painting: Primer + Base Coat + Clear Coat (High Energy/Labor).

- Scrap: Paint defects (dust, sagging, orange peel) typically run 10-15%.

- Assembly: Final check.

Scenario B: Kumho Sunny High Gloss MIC

- Molding: High Gloss Resin + RHCM Mold (Slightly longer cycle time).

- Scrap: Molding defects are recyclable (Runners can be re-ground at low percentages).

- Assembly: Direct to line.

- Result: The MIC solution typically yields a 20-30% Total System Cost Reduction.

- Investment: While the MIC mold (high polish, potentially steam channels) is 15-20% more expensive than a standard mold, the ROI is typically achieved within the first 15,000 units due to the elimination of paint unit costs.

5. Environmental Impact: VOCs and Carbon Footprint

The painting process is the largest contributor to an automotive plant’s environmental footprint.

- VOC Emissions: Even with water-borne paints, the curing process releases solvents. MIC technology is a Zero-VOC process at the assembly level.

- Energy Consumption: Paint shops require massive ovens for curing (140celsius+). Injection molding consumes significantly less energy per part.

- Recyclability: Painted parts are difficult to recycle because the paint layer acts as a contaminant. MIC parts are 100% thermoplastic and can be easily reground and recycled at the end of the vehicle’s life, aligning with EU End-of-Life Vehicle (ELV) Directive.

6. Manufacturing Guidelines for Engineers

Transitioning to High Gloss MIC requires a shift in tooling strategy. You cannot simply shoot high-gloss resin into a standard mold and expect Class-A results.

6.1 Tooling Requirements

- Steel Grade: Use high-quality steels (e.g., S136, NAK80) capable of achieving an A1 SPI Finish (Diamond Polish).

- Cooling Channels: Conformal cooling is recommended to ensure uniform thermal distribution and prevent warpage.

6.2 Preventing “Tiger Stripes” (Flow Instability)

A common defect in high-gloss molding is “Tiger Striping”—alternating glossy and dull bands.

- Root Cause: Unstable flow front due to high shear stress.

- Solution:

- Gate Design: utilize Fan Gates or diaphragm gates to reduce shear rates. Avoid direct pinpoint gates on visible surfaces.

- Injection Profile: Use a “Slow-Fast-Slow” injection speed profile.

- Slow: Through the gate to prevent jetting.

- Fast: To fill the cavity before the frozen layer thickens.

- Slow: At the end of fill to prevent gas burns and flashing.

7. Conclusion: A Proven Alternative

The question is no longer can High Gloss plastics replace paint, but where should they replace paint.

For components like grilles, pillars, mirror housings, and spoilers, Kumho Sunny’s High Gloss PC/ASA and PMMA/ASA alloys offer a validated, mature solution that meets the rigorous demands of global OEMs (including VW TL 527 and GM GMW15572 standards).

By adopting this technology, automakers can achieve a trifecta of benefits:

- Cost Reduction (Elimination of secondary processes).

- Sustainability (Reduced energy and VOCs).

- Aesthetic Durability (Chip and peel resistance).

Ready to evaluate the switch?

The Kumho Sunny Application Engineering team is ready to support your transition with Moldflow analysis, material selection, and on-site trial support.

Technical References & Further Reading

- ASTM D523: Standard Test Method for Specular Gloss.

- ISO 1133: Determination of the Melt Mass-Flow Rate (MFR).

SAE J2527: Performance Based Standard for Accelerated Exposure of Automotive Exterior Materials using a Controlled Irradiance Xenon-Arc Apparatus.

Post time: Jan-21-2026