A Data-Driven Analysis of Specific Modulus, System Costs, and Anisotropic Behavior in Structural Applications

Author: Senior Lightweighting Engineer, Kumho Sunny R&D Center

Category: Lightweighting / Metal Replacement / EV Structure

Read Time: 12 Minutes

Abstract

The transition to Electric Vehicles (EVs) has fundamentally altered the “weight equation.” With battery packs adding 300-600kg to the vehicle mass, the secondary weight spiral demands aggressive mass reduction in structural components. While Aluminum (Al) and Magnesium (Mg) alloys have been the traditional answers to replacing Steel, Long Glass Fiber Reinforced Polypropylene (LGF-PP) has emerged as the superior solution for semi-structural applications. This technical paper analyzes the Specific Strength (Strength-to-Weight Ratio), Creep Resistance, and Total System Cost of LGF-PP versus metals. We present validation data based on ISO 527 and GMW3028 standards to define the engineering boundaries of metal replacement.

1. The Physics of Efficiency: Density vs. Modulus

To determine “which is better,” we must first look at the fundamental material properties. The goal of lightweighting is not just reducing mass ($m$), but maximizing stiffness per unit of mass.

1.1 The Specific Modulus Equation

Engineers often dismiss PP because its absolute stiffness (Young’s Modulus) is lower than metal. However, in bending stiffness design (common for Door Modules and Front End Carriers), the relevant metric is the Specific Modulus

While Steel is roughly 30x stiffer than PP, it is also 6.5x heavier. By increasing the Section Modulus (geometry) of the plastic part—using ribs and honeycombs—we can match the part stiffness of metal at 30-40% lower mass.

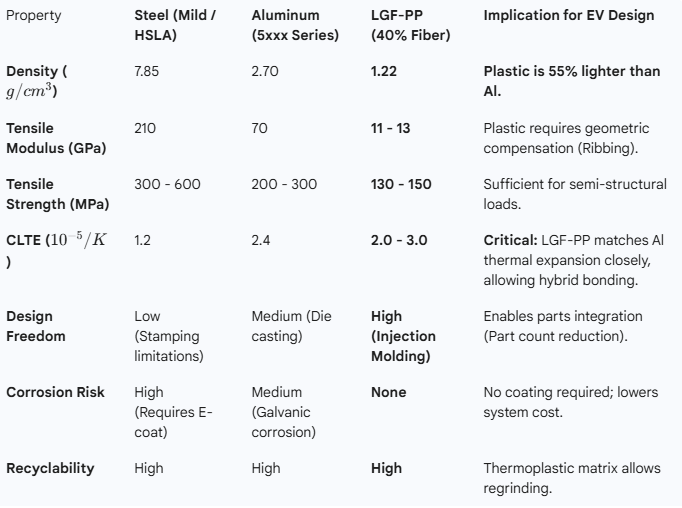

2. Comparative Analysis: LGF-PP vs. Aluminum vs. Steel

The following table benchmarks a typical 40% Long Glass Fiber PP (Kumho Sunny Grade) against standard automotive metals.

Table 1: Material Property & Performance Matrix

Tech Note: Short Glass Fiber (SGF) PP typically offers a modulus of 6-8 GPa. The shift to Long Glass Fiber (LGF) pushes this to 11-13 GPa, bridging the gap to Magnesium alloys. This is achieved by maintaining fiber lengths of >10mm in the pellet, forming a skeletal network within the part.

3. The “Hidden” Variable: Anisotropy and Fiber Orientation

A complex pain point in replacing metal with plastic is Anisotropy. Metals are isotropic (properties are the same in all directions). LGF-PP is anisotropic.

- Flow Direction (Longitudinal): Fibers align with the flow. Strength is maximized (e.g., 150 MPa).

- Cross-Flow Direction (Transverse): Strength is significantly lower (e.g., 80-90 MPa).

The Kumho Sunny Solution: We utilize Moldflow simulation to optimize gate locations, ensuring fibers align with the primary load vectors of the component.

- Standard Reference: ISO 527-1/2.

- Result: By predicting weld lines and fiber orientation tensors, we can achieve safety factors comparable to metal castings.

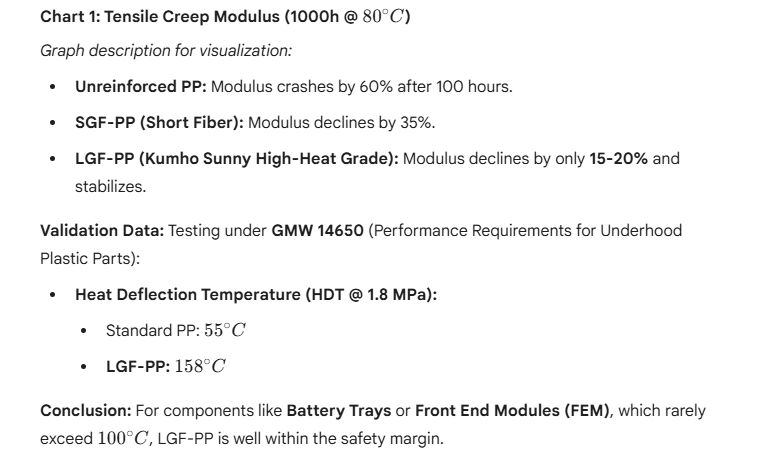

4. Temperature & Creep Performance: The Achilles Heel?

Skeptics argue that plastics “creep” (deform permanently under constant load) and fail at high temperatures. This is where “Tech Authority” requires honesty.

Steel/Al behavior is elastic until yield. PP behavior is viscoelastic.

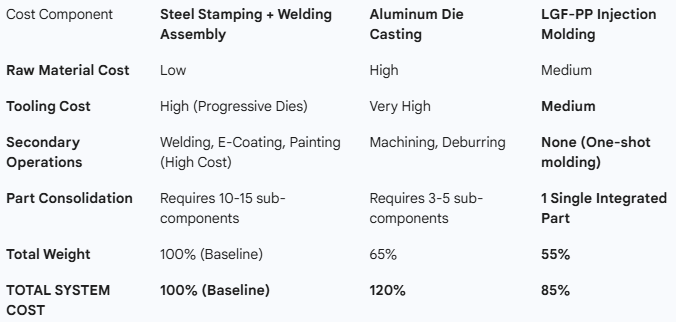

5. Economic Analysis: System Cost vs. Material Cost

Procurement managers often note that LGF-PP ($/kg) is more expensive than Steel. However, automotive engineering works on Cost per Part, not Cost per Kg.

Table 2: Front End Module (FEM) Cost Breakdown

The Integration Advantage: With LGF-PP, functional elements like air ducts, latch supports, and headlamp brackets are molded directly into the carrier. This removes fasteners and assembly labor, which constitutes 30% of the cost in metal assemblies.

6. Real-World Applications in EVs

Which parts are prime candidates for switching from Metal to LGF-PP?

- Instrument Panel (IP) Carriers:

- Old Standard: Magnesium Die Cast or Steel Tube.

- New Standard: LGF-PP.

- Result: 30% weight saving, improved NVH (plastics dampen vibration better than metal).

- Tailgates (Inner Structure):

- Standard: Steel.

- New Standard: LGF-PP + TPO Skin.

- Result: 5kg weight reduction per vehicle.

- EV Battery Pack Top Covers:

- Standard: Aluminum Sheet.

- New Standard: Flame Retardant LGF-PP (UL94 V-0).

- Result: Electrical insulation (dielectric strength) + Lightweighting.

7. Sustainability: The Carbon Footprint (LCA)

Metal production (especially Aluminum smelting) is extremely energy-intensive.

- Production Energy (MJ/kg):

- Aluminum (Primary): ~170 MJ/kg

- Steel: ~30 MJ/kg

- Polypropylene: ~70 MJ/kg

However, because the volume density of PP is so low, the energy required per part is significantly lower. Furthermore, LGF-PP allows for low-temperature processing (230celsius melt vs 700celsius+ for Al casting), further reducing the manufacturing carbon footprint.

Conclusion: The Verdict

So, Glass Fiber Reinforced PP vs. Metal: Which is better?

- Choose Metal (High Strength Steel/Aluminum) if: The part is a primary crash structure (A-Pillar, Chassis Rail) or sees temperatures >160Celsius.

- Choose LGF-PP if: The part is semi-structural (FEM, Door Module, Tailgate, Battery Cover), requires complex geometry integration, and demands maximum weight reduction per dollar.

For the modern EV, the “Metal-to-Plastic” conversion is no longer about making cheap parts; it is about making intelligent, integrated, and lightweight architectures.

At Kumho Sunny, our Fiber-Reinforced Composites (FRC) team assists OEMs in navigating this transition, offering full CAE support to predict anisotropic performance before the mold is even cut.

Post time: Jan-21-2026