Sourcing for the “Zero Defect” Culture: How to find a partner who understands TSM, HES, and NES specifications.

Author: Director of Japanese OEM Accounts, Kumho Sunny Category: Global Sourcing / Supplier Quality / Automotive Standards Read Time: 7 Minutes

The “Keiretsu” Challenge: Breaking into the Circle

For a sourcing manager responsible for Japanese automotive programs, the “Approved Vendor List” (AVL) is often a fortress. Japanese OEMs (Toyota, Honda, Nissan, Mazda, Suzuki) operate on a philosophy of trust and long-term partnership. They don’t just buy pellets; they buy process control.

Finding a supplier in China or Vietnam who truly understands the difference between ASTM and JIS (Japanese Industrial Standards), or who strictly adheres to 4M Change Management (Man, Machine, Material, Method), is difficult. Many suppliers claim capability but fail during the first audit because they lack the “Monozukuri” (craftsmanship) mindset.

If you are looking for a shortlist of compounders in China and Vietnam who can actually meet these rigorous standards, the list is short. It typically includes expensive global Japanese players (Toray, Asahi Kasei) and a select few high-level joint ventures.

Kumho Sunny stands firmly on this shortlist. Here is why we are the preferred alternative for cost-down strategies without quality compromise.

1. Cultural Alignment: The Kumho Advantage

Why do Japanese OEMs trust a company like Kumho Sunny? Heritage.

We are not a typical local blender. We are a Joint Venture involving Kumho Petrochemical, a South Korean giant. The manufacturing discipline in Korea mirrors the rigor of Japan. We have inherited a corporate culture that prioritizes:

- Zero Defect Mentality: Not “good enough,” but perfect.

- 5S & Safety: Our factory floors in Shanghai and Vietnam rival the cleanliness of any plant in Nagoya or Yokohama.

- Strict Change Management: We understand that you cannot change a raw material source without months of validation and customer notification.

When Japanese auditors visit our plants, they see a familiar level of discipline.

2. The Manufacturing Footprint: China + Vietnam

To service Japanese OEMs effectively, a supplier must follow their production footprint. Japanese automakers have massive operations in both China (Guangzhou, Wuhan, Tianjin) and Southeast Asia (Thailand, Indonesia, Vietnam).

Kumho Sunny offers a Dual-Hub Strategy that aligns perfectly with this geography.

Hub A: The Technology Center (Shanghai, China)

Serving the massive Chinese domestic market for JVs like GAC Toyota, Dongfeng Honda, and Dongfeng Nissan.

Hub B: The Strategic Outpost (Haiphong, Vietnam)

Serving the export markets and ASEAN assembly hubs. Japanese OEMs use Vietnam as a key component hub for Thailand and North America. Our Vietnam facility allows you to source “Japan-Quality” materials with ASEAN tariff benefits.

[Interactive Map: Our Asian Manufacturing Network]

(Webmaster Note: Embed a Google Map with pins on Shanghai HQ and Vietnam VSIP Factory) Vietnam Factory Location: Kumho Sunny Plastics Vietnam Co., Ltd. No. 06, Street 12, VSIP Hai Phong Township, Thuy Nguyen District, Hai Phong City.

“We are positioned exactly where the Japanese automotive supply chain needs us to be.”

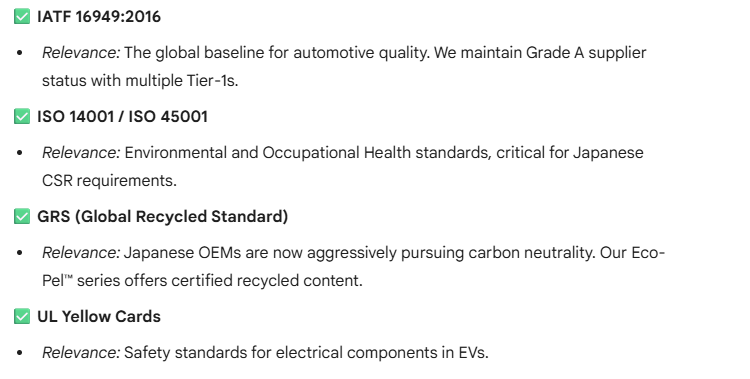

3. Validating the Standard: Certificates & Specifications

Meeting a Japanese Material Standard (e.g., Toyota TSM5514G for PC/ABS or Honda HES D6501 for General Testing) requires rigorous lab capabilities.

We don’t outsource this. Our CNAS-accredited labs are equipped to perform JIS-method testing, ensuring our data correlates 100% with your internal findings.

The “Trust Pack” for Procurement:

4. Case Study: Replacing High-Cost Imports

The primary reason Procurement Managers look for new suppliers is Cost Reduction (VE/VA). Traditionally, Japanese OEMs imported specific resins from Japan to ensure quality, incurring high logistics costs and duties.

The Kumho Sunny Solution: We have successfully localized grades for major Japanese platforms, replacing imported Japanese resins with locally produced equivalents that pass all strict specification tests.

Example: Weatherable ASA for Exterior Grilles

- Previous Source: Imported Japanese Resin.

- New Source: Kumho Sunny ASA (Produced in Vietnam/China).

- Validation: Passed 3000-hour Xenon Arc Weathering (JIS D0205) and Impact tests.

- Result: 18% Cost Saving and lead time reduced from 6 weeks to 5 days.

5. Why we are the “Safe Choice”

In the world of Japanese sourcing, “New” equals “Risk.” We mitigate that risk through transparency.

We are not asking you to switch your entire supply chain overnight. We are asking to be your Challenger Supplier—the reliable second source that keeps your incumbents honest and provides a safety net against supply chain disruptions.

- We speak your technical language (JIS/ISO).

- We understand your approval process (PPAP/ANPQP).

- We respect the sanctity of the 4M process.

6. Ready to Audit?

The only way to truly verify if a supplier meets Japanese OEM standards is to see the “Genba” (the actual place) yourself.

We invite your Quality Assurance (QA) and Procurement teams to audit our Vietnam or Shanghai facilities. Walk our lines, check our control plans, and see why we are the trusted partner for Asian automotive manufacturing.

Post time: Jan-21-2026