In the fields of small household appliances and electronic/electrical equipment, flame-retardant PC/ABS is hailed as a “star material” due to its balanced physical properties, processability, and cost-effectiveness. However, screw boss cracking has long been an incurable pain point for the industry. The resulting assembly failures, shortened product lifespans, and high scrap costs often lead to significant economic and brand reputation losses for enterprises. As a leader in the modified plastics sector, Kumho-Sunny has conducted an in-depth analysis of the root causes of cracking. Leveraging its profound R&D expertise, the company has introduced the KUMHO-SUNNY® series—a solution specifically designed to tackle “stubborn cracking” issues.

Our Core Product Advantages:

Superior Aging Resistance and Toughness Retention Conventional flame-retardant PC/ABS often suffers from poor aging resistance due to molecular chain scission and cross-linking. After several months of storage, these materials can degrade from a “high-toughness” state to an extremely brittle one.

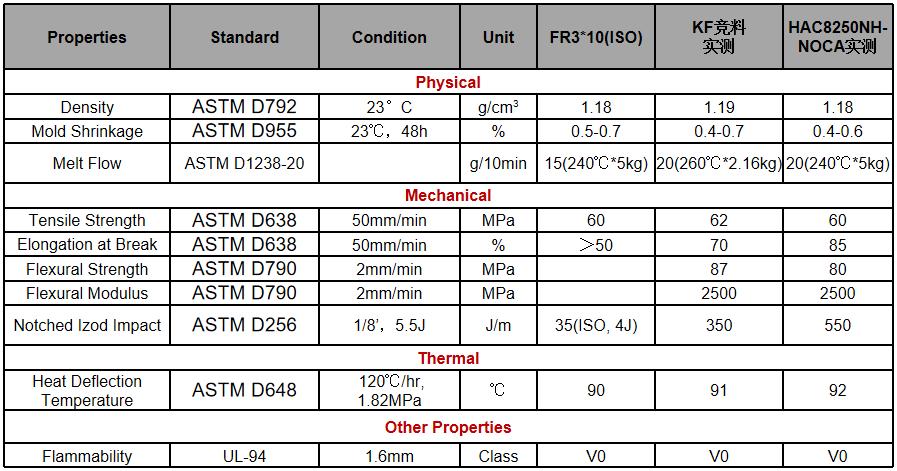

Through rigorous base material selection and formula upgrades, Kumho-Sunny has launched HAC8250NH-NOCA, which delivers exceptional toughness performance:

- Elongation at Break: Leads similar products by more than 15%.

- Impact Resistance: Reaches as high as 550 J/m.

These advancements ensure that products remain robust even after long-term storage and assembly, completely eliminating the “delayed cracking” phenomenon characterized by a long “latency period.”

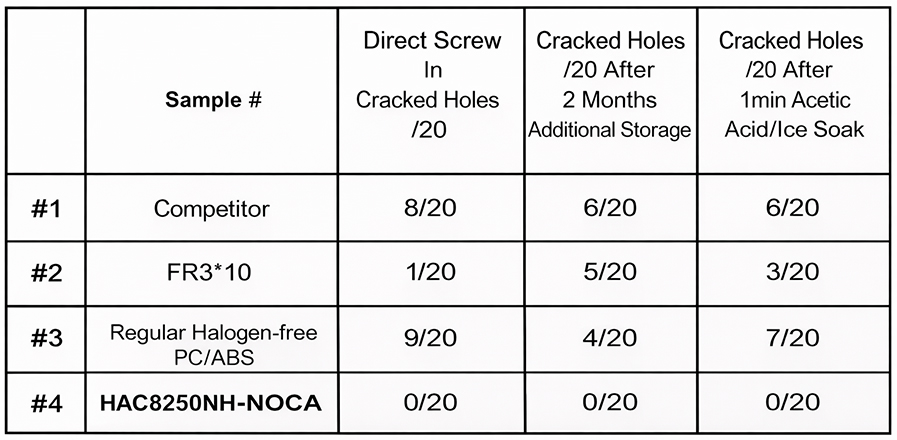

Proven “Zero-Cracking” Performance: In simulated extreme-stress tests for screw boss cracking (including direct self-tapping, long-term storage, and chemical solvent immersion), Kumho-Sunny’s products demonstrated an overwhelming advantage. They are the “undisputed champions” among similar competing products, truly achieving “zero cracking” across all test scenarios.

Excellent Processability and Cost Efficiency: Our products offer not only high toughness but also superior melt flowability (reaching 20 g/10min at 240°C*5kg), which significantly reduces processing costs. Furthermore, their shrinkage rate is closer to that of metal, greatly enhancing the dimensional stability of precision components.

The Chemical Resistance Powerhouse for Extreme Scenarios: For special working conditions involving contact with anti-rust oils or highly corrosive reagents, we have introduced the flame-retardant PC/PBT K8550NH, featuring even stronger chemical resistance. Even after being immersed in highly corrosive glacial acetic acid for 5 minutes, it maintains “zero cracking,” providing ultimate safety and reliability for high-end terminal products.

More than just high-performance materials, Kumho-Sunny provides a comprehensive, “one-stop” solution covering material design, processing guidance, and professional evaluation. Choosing us is more than just selecting a sharp tool to eliminate the “critical flaw” of cracking; it is choosing a professional partner capable of injecting long-term reliability into your products and driving your brand’s premium evolution.

Post time: Dec-29-2025