In an industrial landscape focused on “green carbon reduction” and “quality/efficiency improvement,” finding high-performance materials to replace traditional spray painting has become a key trend. Drawing on deep expertise in modification technology, Kumho-Sunny has “evolved” PMMA to create a paint-free PMMA alloy. With its superior visual appeal and rigorous durability, it has earned a reputation as the industry’s “spray-painting killer”.

Our Core Advantages:

Extreme Surface Hardness & Scratch Resistance: While traditional paint-free materials like ABS or PP are often criticized for scratching easily, this evolved PMMA alloy achieves a pencil hardness of 1H or higher. This allows parts to maintain a mirror-like finish over long periods without the need for protective paint.

“Deep” High-Gloss Black Aesthetics: Utilizing unique phase control and pigment dispersion technologies, the alloy achieves extreme blackness (with an L-value as low as 1) and intense mirror reflection. It delivers a more profound visual impact than traditional materials, perfectly replicating the luxury feel of piano lacquer.

Superior Weatherability & Chemical Stability: PMMA is naturally resistant to UV rays. Even after rigorous, long-cycle xenon lamp aging tests, this alloy maintains stable color and gloss without yellowing or embrittlement. It also features excellent resistance to lipids and chemicals, making it ideal for the complex environments of automotive and home appliance sectors.

Targeted Performance Optimization:

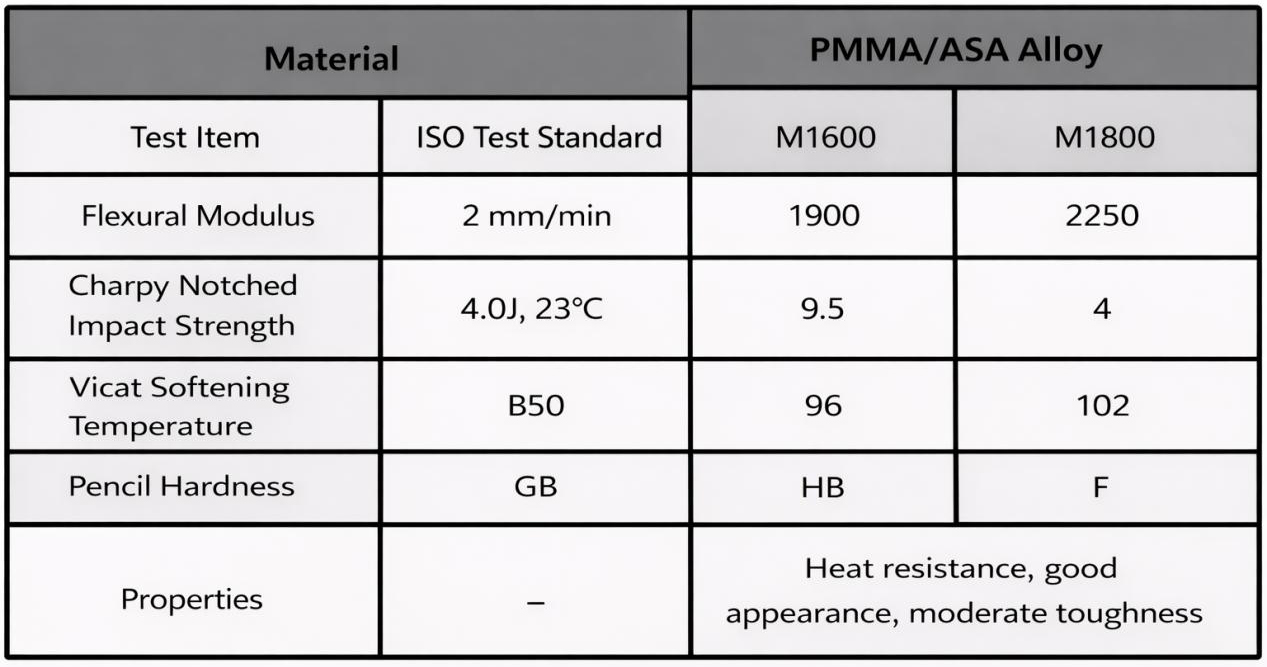

We have introduced two core grades designed for specific application scenarios:

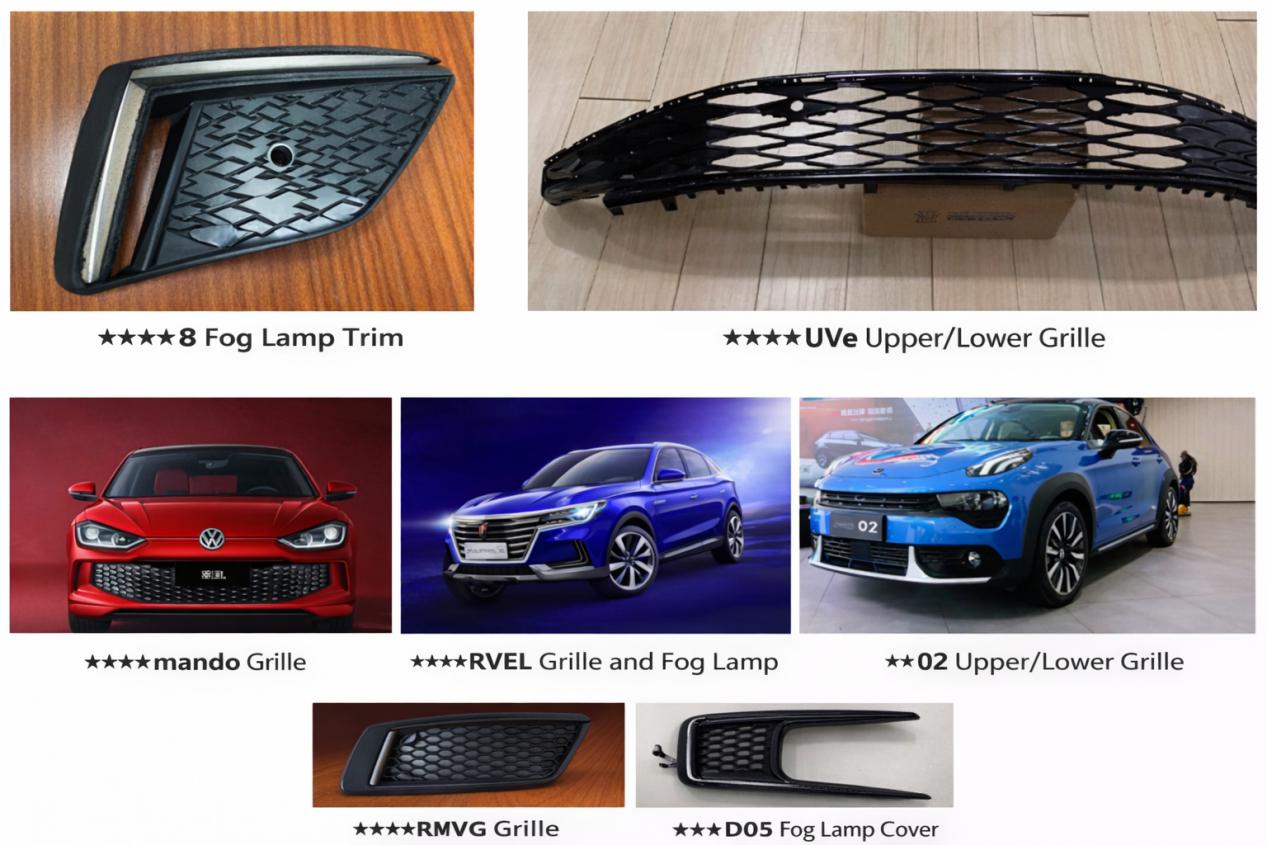

M1600 (High Toughness Type): This grade addresses the inherent brittleness of pure PMMA. It offers outstanding impact resistance and is suitable for collision-prone areas such as front grilles and rearview mirrors.

M1800 (Heat Resistant Type): Featuring a higher heat deflection temperature, this grade is specifically designed for components like pillar garnishes and roof spoilers that are subject to intense sun exposure during summer.

Application Scenarios and Value:

Currently, this material has achieved large-scale mass production within the automotive industry, covering components for mid-to-high-end models such as front grilles, fog lamp covers, B/C pillar garnishes, triangle trims, and rearview mirror housings. At the same time, it delivers outstanding performance in the fields of high-end home appliances and smart home devices.

Conclusion:

Choosing Kumho-Sunny PMMA alloy is more than just selecting a material; it is choosing an exterior solution characterized by low carbon emissions, high yield rates, and low comprehensive costs. Through evolved technology, we provide paint-free solutions with the performance to truly surpass traditional painting.

Post time: Dec-29-2025