A Scientific Molding Approach to Stabilizing the Process Window and Reducing Scrap

Author: Senior Technical Service Engineer, Kumho Sunny R&D Center Category: Injection Molding / Process Optimization / Defect Analysis Read Time: 12 Minutes

Abstract

Polycarbonate/Acrylonitrile Butadiene Styrene (PC/ABS) alloys are the workhorse of the automotive and electronics industries, prized for balancing the heat resistance of PC with the processability of ABS. However, this immiscible blend is notoriously sensitive to moisture hydrolysis, shear sensitivity, and residual stress. This technical paper moves beyond basic “symptom-fix” lists. We analyze the rheological and thermal root causes of common defects—specifically Silver Streaks (Splay), Jetting, and Stress Cracking—and provide data-driven solutions based on Scientific Molding principles and ISO 294 processing standards.

1. The Material Science Context: Why is PC/ABS “Touchy”?

To troubleshoot PC/ABS, one must understand its morphology. It is a physical alloy where ABS rubber particles are dispersed within a rigid PC matrix.

The Conflict: You need high heat to push the viscous PC, but too much heat/shear degrades the ABS (butadiene rubber), leading to property loss. Furthermore, the PC ester bonds are highly hygroscopic and prone to hydrolysis.

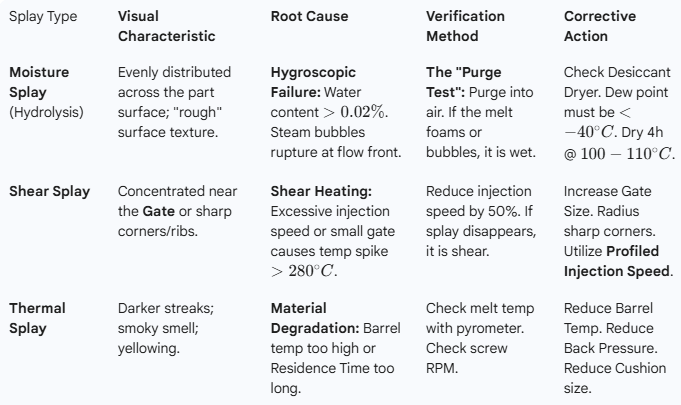

2. Defect #1: Silver Streaks (Splay Marks)

Diagnosis: Moisture vs. Shear vs. Heat

Silver streaks are the most frequent reason for PC/ABS rejection. They appear as U-shaped silvery lines radiating from the gate. Many engineers assume “Moisture” immediately, but there are three distinct types.

Table 1: The Silver Streak Differential Diagnosis Matrix

Tech Tip: For PC/ABS, the critical moisture content limit is 0.02%. Standard ABS can tolerate 0.1%, but PC/ABS cannot. If hydrolysis occurs, the molecular weight drops, and impact strength can decrease by 40% even if the part looks okay.

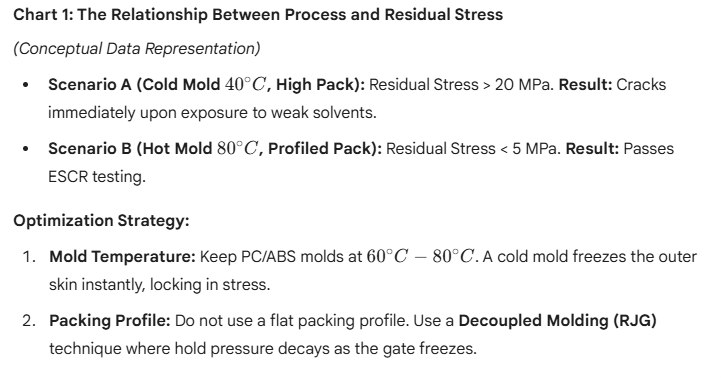

3. Defect #2: Stress Cracking and Chemical Failure

The Silent Killer

A part may look perfect off the press but fail weeks later during assembly or in the field. This is Environmental Stress Cracking (ESC), often caused by high residual stress combined with chemical exposure (paints, greases, thread lockers).

3.1 Measuring Residual Stress

Residual stress is frozen into the part when the polymer chains are stretched during filling and then cooled before they can relax.

- Test Standard: ASTM D543 (Chemical Resistance) or Solvent Immersion Test (glacial acetic acid / ethyl acetate).

- Mechanism: High packing pressure or low mold temperature freezes the orientation.

4. Defect #3: Peeling (Delamination)

When the Blend Separates

Peeling manifests as thin layers of skin flaking off, usually at the gate. This indicates a breakdown in the compatibility between the PC and ABS phases, or high shear stress separating the layers.

Common Causes:

- Contamination: PE or PP contamination (even 1%) acts as a release agent between layers.

- Cold Slug: A cold plug of material enters the cavity and doesn’t fuse.

- High Shear: Excessive shear rate separates the butadiene rubber phase from the SAN matrix.

The Fix:

- Cold Slug Well: Ensure the runner system has a sufficient cold slug well extension (typically 1.5x runner diameter).

- Material Compatibility: Ensure the PC/ABS grade is formulated with robust compatibilizers (like Kumho Sunny’s HAC Series).

5. Defect #4: Knit Lines (Weld Lines) Strength

Structural, Not Just Visual

In PC/ABS, the weld line is often the weakest point because the flow fronts cool rapidly. Unlike crystalline materials (PA66), amorphous PC/ABS does not re-crystallize across the joint; it relies purely on chain entanglement.

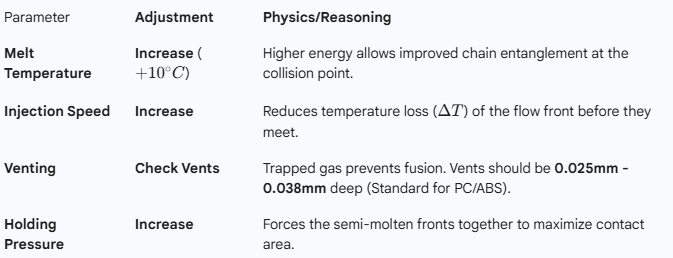

Table 2: Knit Line Optimization Parameters

Validation Standard: ISO 527. A good weld line should retain >80% of the tensile strength of the base material. If retention is <50%, process adjustment is required.

6. Scientific Molding: Recommended Processing Window

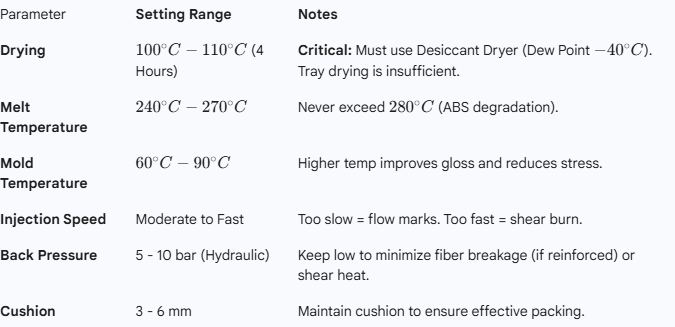

To avoid the defects above, we recommend adhering to a defined process window. Below is a baseline for a standard High-Impact PC/ABS (e.g., PC/ABS alloy with 70% PC).

Table 3: Typical Process Settings (Kumho Sunny PC/ABS)

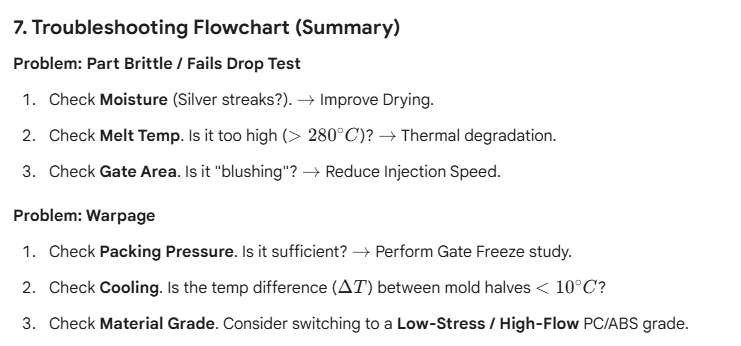

Conclusion: Process Stability Starts with Material Selection

While process parameters are critical, the intrinsic stability of the resin is the foundation. Generic PC/ABS blends often have narrow processing windows, leading to high scrap rates when ambient humidity changes or cycle times fluctuate.

Kumho Sunny’s PC/ABS series is engineered with broadened processing windows and enhanced thermal stability additives, allowing molders to run robust processes with lower rejection rates.

Post time: Jan-21-2026