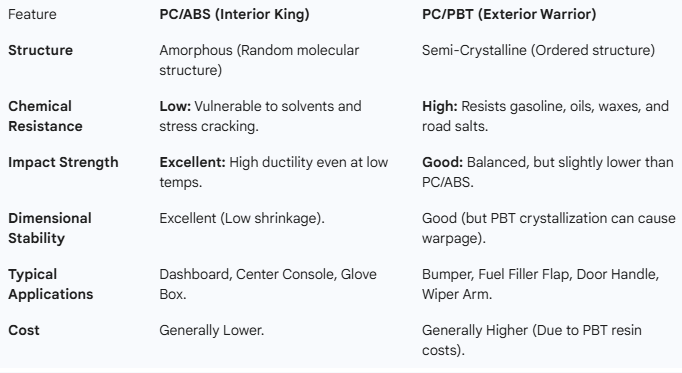

The primary difference between PC/ABS and PC/PBT lies in their chemical resistance and crystalline structure. PC/ABS (Polycarbonate/Acrylonitrile Butadiene Styrene) is an amorphous alloy known for superior impact strength and ductility, making it the standard for automotive interiors. In contrast, PC/PBT (Polycarbonate/Polybutylene Terephthalate) contains a semi-crystalline component that provides exceptional resistance to fuels, oils, and solvents, making it the critical choice for automotive exteriors and functional parts exposed to harsh chemicals.

For engineers and buyers, the decision comes down to one question: Will the part touch oil, gas, or grease? If yes, choose PC/PBT. If no, PC/ABS is likely the more cost-effective and impact-resistant option.

Deep Dive: When to Choose PC/ABS

PC/ABS is a blend of the toughness of PC and the processability of ABS. It is the “default” engineering plastic for the automotive cabin.

- Why it wins for Interiors:

- Crash Safety: It doesn’t shatter into sharp shards upon impact (high ductility), which is crucial for passenger safety during a crash.

- Aesthetics: It provides a high-quality surface finish, whether painted, plated, or left as-molded (using Low Gloss grades).

- Processing: It has a wider processing window than PBT-based alloys.

Common Risk: DO NOT use standard PC/ABS in areas where it might be wiped with aggressive cleaners or exposed to engine grease. This causes Environmental Stress Cracking (ESC).

Related Troubleshooting: Already facing cracking or surface defects in your PC/ABS parts? Check our guide on Troubleshooting Common Injection Molding Defects.

Deep Dive: When to Choose PC/PBT

PC/PBT introduces a crystalline polyester (PBT) into the matrix. Crystals act like a shield against chemical attack.

- Why it wins for Exteriors:

- The “Gas Station” Test: If fuel drips on a fuel filler flap made of PC/ABS, it will crack. PC/PBT will remain unaffected.

- Weatherability: When properly stabilized, it withstands UV exposure and rain better than ABS-based alloys.

- Stiffness: It offers higher rigidity, which is good for structural brackets and mirror housings.

Common Risk: PBT creates crystals as it cools, which causes the material to shrink more than amorphous plastics. This can lead to Warpage if the mold cooling isn’t balanced.

Can I use them interchangeably?

Generally, No.

- Swapping PC/ABS to PC/PBT: You might solve a chemical issue, but you may introduce warpage issues or increase costs unnecessarily.

- Swapping PC/PBT to PC/ABS: This is dangerous for exterior parts. The part might look fine initially but will fail catastrophically after a few months of exposure to road salts and car wash chemicals.

Conclusion

Selecting the right alloy prevents costly recalls.

- Use PC/ABS for Safety & Style inside the cabin.

- Use PC/PBT for Resilience & Resistance outside the vehicle.

At Kumho Sunny, we offer a full spectrum of both alloys, including our high-performance HAC series (PC/ABS) and chemical-resistant HPC series (PC/PBT).

Looking for a cheaper alternative without compromising quality? It is possible to reduce costs by optimizing your grade selection.

Read more: Are there cost-effective PC/ABS alternatives in the Asian market?

Need a Technical Data Sheet (TDS) to compare specific values?

Download Material Data Sheets | Ask an Engineer

Post time: Jan-21-2026